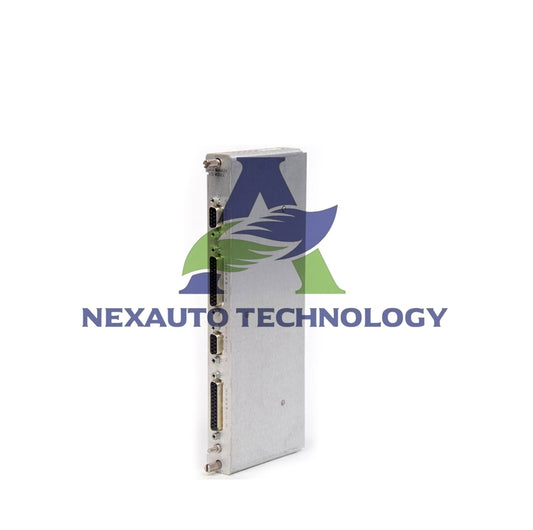

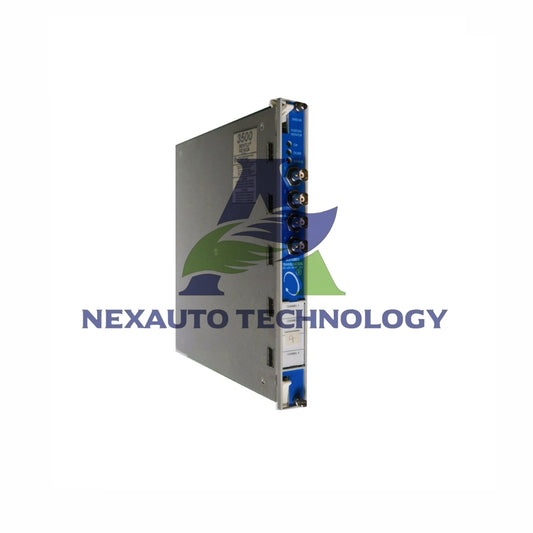

How Does the Bently Nevada 3500/05 System Rack Safeguard Your Critical Operations?

In industrial automation, unplanned equipment failure is a primary cause of costly downtime. Therefore, robust machinery protection is not a luxury—it's a necessity. The Bently Nevada 3500/05 System Rack serves as a frontline defense, specifically designed to monitor vital assets and prevent catastrophic breakdowns.

The Core Function: Continuous Condition Monitoring

This system rack performs essential vibration and temperature surveillance. It constantly checks the health of rotating equipment like turbines, compressors, and large pumps. By tracking these key parameters, it provides an early warning system for mechanical issues such as imbalance, misalignment, or bearing wear.

Engineering Reliability into Your Process

Engineers trust the 3500/05 for its modular and rugged design. Moreover, its architecture allows for seamless integration into existing Distributed Control Systems (DCS) and PLC networks. This interoperability is crucial for creating a unified and responsive operational technology (OT) environment.

Application Case: Power Generation Plant

A combined-cycle power plant in Texas faced repeated turbine trip issues. After installing 3500/05 racks, the system identified specific vibration signatures linked to bearing lubrication problems. This insight allowed maintenance teams to adjust oil flow rates. Consequently, the plant reduced unscheduled turbine trips by 70% within one year, saving an estimated $850,000 in outage costs and lost revenue.

Solution Scenario: Offshore Oil & Gas Platform

On a North Sea platform, centrifugal gas compressors are critical for production. The harsh environment accelerated component wear. Integrating 3500/05 racks enabled real-time monitoring of radial and axial vibration. The data revealed a compressor rotor imbalance developing over 4 months. This early detection enabled a planned shutdown for rebalancing during a weather window, avoiding a 14-day forced outage that would have cost over $2.1 million in deferred production.

The Trend Towards Predictive Operations

The industry is shifting from reactive to predictive maintenance. In this context, the 3500/05 is more than a protector; it's a data source. Its accurate, real-time signals are foundational for advanced analytics platforms aiming to predict remaining useful life and optimize maintenance schedules. We're seeing a trend where this historical protection data is now being used to train AI models for fault prediction.

Why This System Remains a Standard

Bently Nevada, a part of Baker Hughes, has established authority in condition monitoring. Their 3500 platform is an industry standard with over 40 years of evolution. The 3500/05 rack embodies decades of expertise, offering proven reliability that minimizes risk. For asset managers, this trustworthiness is invaluable when justifying capital expenditure for protection systems.

Implementation Scenario: Chemical Processing Facility

A major chemical processor retrofitted 3500/05 systems across 12 reactor charge pumps. The monitoring data not only provided protection but also revealed operational inefficiencies. By analyzing vibration trends against process parameters, engineers optimized pump speeds. This adjustment reduced energy consumption by 18% per pump, resulting in annual savings exceeding $65,000 while extending mean time between repairs (MTBR) by 30%.

Author's Perspective: The Value Proposition

From my experience in plant operations, the true value of a system like the 3500/05 extends beyond avoiding disasters. It provides operational intelligence. The ability to trend machine health against production rates creates opportunities for optimization that directly impact the bottom line. My recommendation is to view such protection systems not as cost centers, but as data assets that enable smarter, more profitable operations.

Final Recommendation

If your operation depends on critical rotating machinery, a dedicated protection system is non-negotiable. The Bently Nevada 3500/05 offers a time-tested, integrated solution. It turns unpredictable failures into manageable, scheduled events, safeguarding both your productivity and your bottom line. The case studies show ROI is typically achieved within 12-18 months through avoided downtime alone.

FAQ: Bently Nevada 3500/05 System Rack

Q1: What type of machinery is the 3500/05 rack best suited for?

A1: It is ideally used for critical high-speed rotating equipment, including gas & steam turbines, centrifugal compressors, large pumps, and electric motors.

Q2: Can the 3500/05 system communicate with modern IIoT platforms?

A2: Yes. While a core protection system, its data can be interfaced with SCADA, historians, and IIoT platforms via standard protocols for broader analytics and predictive maintenance initiatives.

Q3: How does this system reduce operational costs?

A3: By preventing catastrophic failures and enabling condition-based maintenance, it drastically cuts downtime costs, reduces spare part waste from unnecessary overhauls, and can lower energy use by ensuring machines run optimally.

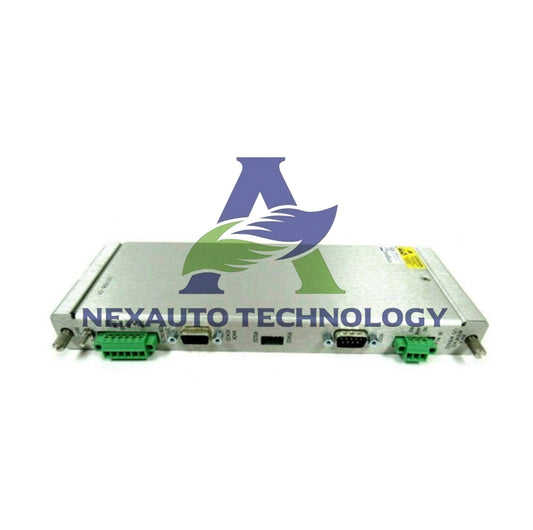

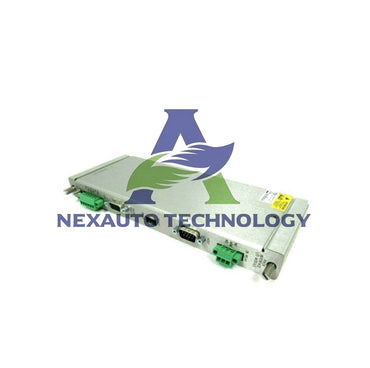

Q4: Is the 3500/05 rack suitable for harsh industrial environments?

A4: Absolutely. It is engineered with rugged construction to reliably operate in environments with extreme temperatures, humidity, and vibration commonly found in plants and offshore platforms.

Q5: What's the difference between protection and monitoring with this system?

A5: The 3500/05 performs both. Its primary role is protection—initiating automatic shutdowns if parameters exceed safe limits to prevent damage. Simultaneously, it provides continuous monitoring data for diagnostics and trend analysis.

Check below popular items for more information in Nex-Auto Technology.

| Model | Title | Link |

|---|---|---|

| 3500/05-01-03-00-00-01 | Bently Nevada System Rack | Learn More |

| 3500/05-01-02-00-00-01 | Bently Nevada System Rack | Learn More |

| 3500/05-01-01-00-00-01 | Bently Nevada System Rack | Learn More |

| 3500/05-01-03-01-00-01 | System Rack Bently Nevada | Learn More |

| 3500/05-02-04-01-00-00 | System Rack Bently Nevada | Learn More |

| 3500/05-02-05-00-00-00 | Bently Nevada 3500/05 Rack 12 inch Rack | Learn More |

| 3500/05-02-04-00-00-01 | Bently Nevada 3500/05 Rack 12 inch | Learn More |

| 3500/05-02-04-01-00-01 | Panel Mount Rack Bently Nevada | Learn More |

| 3500/05-02-05-00-00-01 | 12 inch Mini Rack Bently Nevada | Learn More |

| 3500/05-01-03-00-00-00 | System Rack Bently Nevada | Learn More |