How Can Predictive Maintenance Stop Rotating Machinery Failures Using PLC and DCS Integration?

Predictive maintenance is revolutionizing industrial operations by forecasting machine problems before they occur. This proactive approach leverages data analytics to predict equipment breakdowns. Plants can thus prevent unplanned stops and expensive damage. Industry leaders like Bently Nevada, part of Baker Hughes, provide essential condition monitoring technologies for this strategy.

The Foundation of Proactive Machine Care

This methodology depends on uninterrupted surveillance of asset health. Dedicated sensors measure key indicators such as vibration, heat, and pressure levels. Sophisticated software examines this live data feed. It pinpoints minor deviations that signal possible wear. Consequently, repairs happen only when evidence demands, maximizing resource efficiency.

Connecting Health Monitoring to Factory Control Systems

Modern monitoring platforms integrate directly with existing PLC and DCS architectures. Vibration sensors and monitors transmit vital health metrics to the central control network. Furthermore, this merger offers a single pane of glass for operations. Staff visualize both production parameters and equipment condition simultaneously. As a result, facility-wide situational awareness and response improve.

From Sensor Data to Preventive Actions

Sensors gather information from rotating assets like pumps, compressors, and turbines. This data flows into the analysis software for instant evaluation. The system compares readings against normal benchmarks to find irregularities. In addition, it creates prioritized warnings within the DCS console. Technicians then get specific tasks with diagnostic details to guide them.

Averting Major Equipment Disasters

The core value lies in early defect identification. For instance, escalating vibration trends often reveal deteriorating bearings. Engineers can plan a repair for the next scheduled maintenance window. However, without this alert, a complete bearing failure might happen. Such an event could lead to secondary damage, with costs for repairs and lost output exceeding $500,000.

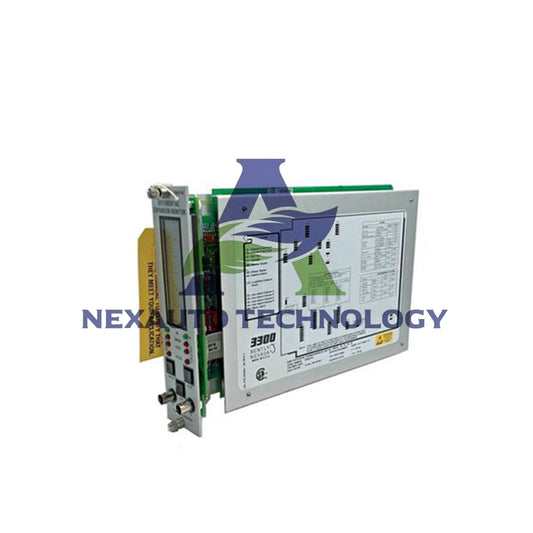

Real-World Application: A Petrochemical Plant Success

A large chemical facility connected a Bently Nevada 3500 monitoring system to its distributed control system. The setup watched over 150 essential pumps and fans. It identified a growing imbalance in a key circulation pump. Analysis revealed a 40% jump in vibration levels. Therefore, the team scheduled an intervention during a small process adjustment. They found and swapped a worn impeller. This proactive move prevented an estimated 21 days of downtime, saving over $2.3 million in potential production losses.

Another Case: Gas Compressor Protection

At a natural gas processing site, integrated monitoring detected early signs of misalignment in a critical turbo-compressor. The PLC received alerts showing a 25% increase in axial vibration. This allowed for a planned realignment during a routine inspection, avoiding a forced shutdown that would have cost $1.8 million per day in lost throughput. The data integration enabled a coordinated response between process and maintenance teams.

The Path Forward for Smart Factory Health

The industrial trend is advancing toward even tighter integration and intelligent data use. Current systems use artificial intelligence to enhance failure forecast precision. Moreover, connectivity now expands to cloud-based platforms for cross-site analysis. From my professional viewpoint, this progression is building the foundation for self-optimizing plants. Facilities implementing these integrated solutions achieve a strong market edge through unmatched operational uptime.

Guidelines for Successful Deployment

Begin with your most vital and high-value machinery. Select a monitoring solution that supports universal communication standards. Moreover, provide combined training for operations and maintenance personnel on the new system. This builds a shared culture focused on prevention. In my experience, fostering this collaborative mindset is equally important as installing the technology for realizing full benefits.

Frequently Asked Questions

Q1: What is the biggest benefit of linking vibration analysis to control systems?

A1: The primary benefit is consolidated operational awareness. Control room operators access process data and machine wellness information on a single interface, leading to quicker, more effective actions.

Q2: How is condition-based predictive maintenance different from time-based preventive care?

A2: Time-based maintenance follows a fixed calendar schedule. Condition-based predictive maintenance, however, responds to the real-time state of the equipment, eliminating superfluous tasks and parts replacement.

Q3: Are monitoring systems like Bently Nevada compatible with all major control system vendors?

A3: Yes, generally they are. They employ open industrial networks such as Modbus TCP, OPC UA, and Profinet to ensure interoperability with leading PLC and DCS brands like Siemens, Rockwell Automation, and Yokogawa.

Q4: What specific machine problems can these integrated systems foresee?

A4: They reliably predict common rotating equipment faults including imbalance, shaft misalignment, rolling element bearing wear, gear tooth damage, pump cavitation, and aerodynamic or mechanical rub conditions.

Q5: Does the financial return justify the initial setup cost?

A5: Typically, yes. Preventing just one major breakdown often covers the entire system investment. Further financial gains come from lower inventory costs for spare parts and better utilization of maintenance staff time.

Check below popular items for more information in Nex-Auto Technology.