Enhancing Predictive Maintenance with Bently Nevada's 330101 Vibration Probe

Effective machinery health monitoring is essential for industrial safety and operational efficiency. As a result, predictive maintenance has become a cornerstone of modern plant management. Bently Nevada, an industry leader in asset protection, offers a vital tool with its 330101 series probe. This high-precision device seamlessly integrates with 3300 XL monitoring systems, providing reliable data to prevent unexpected equipment failures and minimize costly downtime.

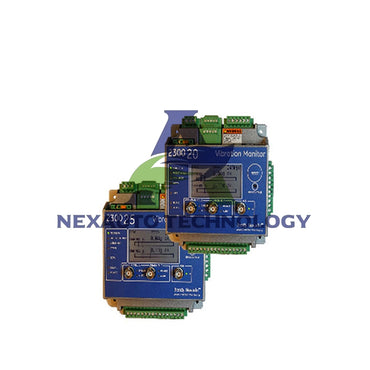

Key Features of the 3300 XL 8mm Probe

The 330101 probe excels due to its precision engineering for measuring shaft vibration. It delivers accurate data on machinery dynamics, a critical indicator of overall equipment health. Moreover, its durable construction ensures consistent operation in demanding environments like refineries and power plants. Consequently, maintenance teams gain a dependable sensor for ongoing condition assessment, forming the foundation of a robust predictive strategy.

Integration and Application in Modern Control Systems

A successful predictive program requires seamless system integration. The 330101 probe connects directly to the established 3300 XL framework. In addition, this integration enables smooth data transfer into broader industrial control systems, including PLCs and DCS. Therefore, operators can centralize monitoring efforts and make timely, data-informed maintenance decisions, enhancing overall factory automation effectiveness.

Application Scenario: Gas Compressor Monitoring

A practical application involves monitoring a natural gas pipeline compressor. In this scenario, the 330101 probe was installed on the compressor's high-speed shaft. Baseline vibration levels were established at 2.0 mils peak-to-peak. During operation, the system detected a steady increase to 3.8 mils, accompanied by a shift in the vibration frequency spectrum. This data, processed through the 3300 XL monitor, indicated developing bearing wear. As a result, the maintenance team scheduled an intervention during the next planned shutdown, avoiding an unplanned outage estimated to cost over $120,000 in lost production. This case demonstrates how precise data enables condition-based maintenance.

Industry Trends and Author Commentary

The industrial sector is rapidly embracing the Industrial Internet of Things (IIoT). In my view, sensors like the 330101 are the essential data-gathering nodes for this digital transformation. They provide the raw operational intelligence that fuels advanced analytics. However, technology alone is not a solution. The greatest value emerges when reliable hardware, like this proven probe, is combined with skilled analysis and strong maintenance processes. Companies that master this integration will lead in operational excellence and profitability.

Implementing a Proactive Maintenance Solution

Adopting this vibration monitoring solution tackles core industrial challenges. It enables the early detection of issues such as imbalance, misalignment, or bearing defects in critical assets like turbines, pumps, and fans. This proactive approach directly reduces unplanned stoppages and extends the service life of expensive machinery. Therefore, implementing such a specialized monitoring system is a strategic investment that protects capital assets and ensures production continuity.

FAQs

Q1: What is the primary function of the Bently Nevada 330101 probe?

A1: Its main function is to provide precise vibration measurement for the predictive maintenance of rotating industrial machinery.

Q2: Which monitoring system is this probe compatible with?

A2: It is designed for direct compatibility and integration with the Bently Nevada 3300 XL series monitoring system.

Q3: In which industries is this vibration probe commonly used?

A3: It is widely deployed in oil and gas, power generation, chemical processing, and heavy manufacturing industries.

Q4: How does this device contribute to plant safety?

A4: By enabling the early detection of mechanical faults, it helps prevent catastrophic machine failures, thereby protecting personnel and assets.

Q5: What makes this probe suitable for harsh environments?

A5: Its robust design and construction ensure accurate, reliable performance under extreme temperatures, pressures, and vibrations found in industrial settings.

Check below popular items for more information in Nex-Auto Technology.

| Model | Title | Link |

|---|---|---|

| 330101-00-36-10-02-CN | Bently Nevada Proximity Probe | Learn More |

| 330101-00-52-10-02-CN | Proximity Probe | Learn More |

| 330101-00-15-20-02-CN | Bently Nevada Proximity Probe | Learn More |

| 330101-00-16-10-01-CN | Bently Nevada Proximity Probe | Learn More |

| 330101-00-19-10-01-CN | Bently Nevada Proximity Probes | Learn More |

| 330101-33-53-10-02-CN | 3300 XL 8 mm Proximity Probe | Learn More |

| 330101-00-11-10-02-CN | 3300 XL 8 mm Probe | Learn More |

| 330101-00-33-10-02-CN | Bently Nevada Proximity Probe | Learn More |

| 330101-00-20-10-01-CN | Proximity Probe | Learn More |

| 330101-00-96-10-02-CN | Bently Nevada Probe | Learn More |

| 330101-00-34-10-02-CN | Bently Nevada Proximity Probe | Learn More |

| 330101-00-22-05-02-CN | Bently Nevada Proximity Probe | Learn More |

| 330101-00-35-10-01-CN | 3300 XL 8 mm Probe Without Armor | Learn More |

| 330101-20-55-10-01-CN | 3300 XL 8 mm Probe | Learn More |

| 330101-35-70-10-01-CN | Bently Nevada Proximity Probe | Learn More |

| 330101-40-75-10-01-CN | Proximity Probe Bently Nevada | Learn More |

| 330101-55-90-10-01-CN | 3300 XL 8 mm Probe | Learn More |

| 330101-00-59-15-02-CN | Bently Nevada Proximity Probes | Learn More |

| 330101-00-30-50-02-CN | 3300 XL 8 mm Proximity Probe | Learn More |

| 330101-00-43-10-02-CN | Bently Nevada Proximity Probe | Learn More |

| 330101-00-28-20-02-CN | Bently Nevada Proximity Probe | Learn More |

| 330101-00-25-05-02-CN | Proximity Probe | Learn More |

| 330101-00-96-05-02-00 | Bently Nevada Proximity Probe | Learn More |

| 330101-00-53-05-02-00 | 3300 XL 8 mm Probe | Learn More |

| 330101-00-20-05-01-CN | 3300 XL 8 mm Proximity Probe | Learn More |

| 330101-00-60-05-02-00 | Bently Nevada Proximity Probe | Learn More |

| 330101-00-25-05-01-CN | Proximity Probe Bently Nevada | Learn More |

| 330101-16-28-10-12-CN | 3300 XL 8 mm Probe Bently Nevada | Learn More |

| 330101-33-53-10-12-CN | 3300 XL 8 mm Probe Bently Nevada | Learn More |

| 330101-00-90-05-02-CN | Bently Nevada Proximity Probes | Learn More |