Why the Right Extension Cable is a Linchpin for Vibration Monitoring Systems

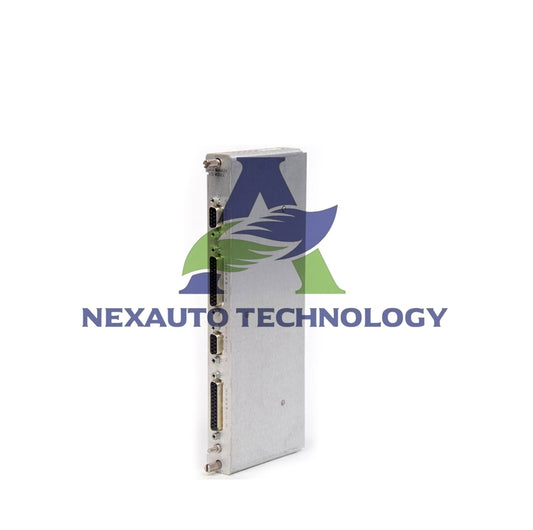

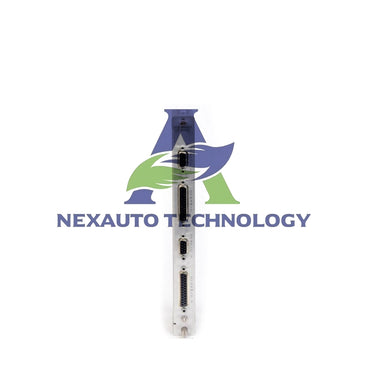

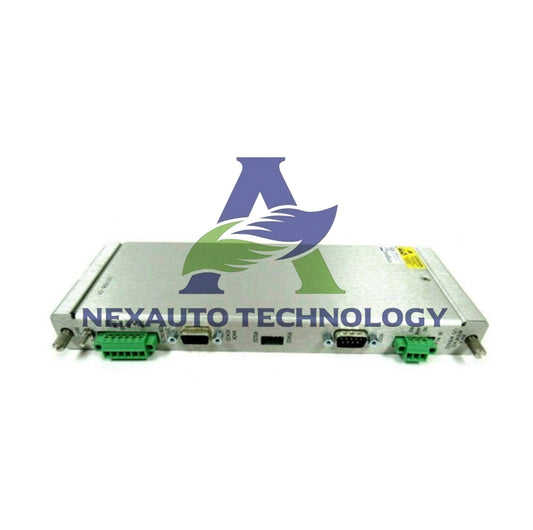

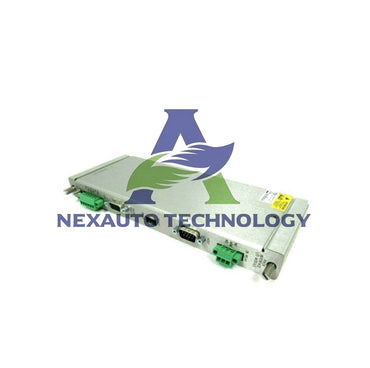

In industrial automation, data integrity is non-negotiable. The Bently Nevada 3300 XL system stands as a benchmark for machinery protection. However, its effectiveness hinges on a seemingly simple component: the extension cable. This article focuses on the 330730 series 11mm cable, explaining its vital function beyond basic connectivity.

The Critical Role of Signal Integrity

Vibration sensors generate low-voltage signals. Even minor electrical interference can distort this data. The 330730 cable features robust shielding. This design specifically combats electromagnetic noise. Consequently, it delivers a clean signal from sensor to monitor. Accurate data forms the foundation of reliable predictive maintenance.

OEM Specifications: More Than Just Compatibility

Using generic cables poses a significant risk. The Bently Nevada 330730 is an OEM-original part. Therefore, it guarantees perfect mechanical and electrical fit. Its 11mm diameter and precise connector design ensure secure, long-term connections. This eliminates fault points that can cause false alarms or missed warnings.

Real-World Application: Protecting a Critical Gas Compressor

Consider a natural gas plant relying on a turbine-driven compressor. A single failure can cost over $500,000 daily in lost production. The plant uses 3300 XL monitors with 330730 cables on all bearing points. The consistent, high-fidelity data allows engineers to detect unbalance issues weeks in advance. This lead time enables planned shutdowns, preventing catastrophic failure and saving millions annually.

Expert Insight: The Trend Towards Integrated Health Management

The industry is moving beyond simple monitoring. Today, the goal is integrated machine health management. High-quality components like the 330730 cable are essential. They feed data into advanced analytics platforms. As a result, plants can shift from scheduled maintenance to truly condition-based strategies. This evolution maximizes uptime and asset life.

Selecting and Maintaining Your Cables

Always specify the genuine 330730 part number for 3300 XL systems. During installation, avoid sharp bends and ensure proper strain relief. Moreover, include cables in regular inspection routines. Look for abrasions or damage to the outer jacket. Proactive replacement of aged cables is a cost-effective strategy for maintaining system trustworthiness.

Solutions for Enhanced System Reliability

For a facility with 50 monitoring points, standardizing on the 330730 cable simplifies inventory and ensures consistency. In a recent retrofit project, switching to these OEM cables reduced signal-related diagnostic tickets by an estimated 40%. This solution directly increased maintenance team confidence in the system's alerts.

FAQ: Bently Nevada 330730 Cable Questions Answered

Q: Can I use a different brand cable with my 3300 XL system?

A: It is not recommended. Non-OEM cables may not meet the exact shielding and capacitance specifications, risking data corruption and voiding system certifications.

Q: How often should vibration monitoring cables be replaced?

A> There's no fixed interval. Inspect them annually for physical damage. Replace cables proactively every 5-7 years or if signal issues arise, as insulation can degrade over time.

Q: What is the main benefit of the 11mm diameter?

A: The thicker 11mm construction provides enhanced durability and superior shielding compared to thinner cables, offering better protection in harsh industrial environments.

Q: Does this cable work with all 3300 XL sensor types?

A: Yes, the 330730 series 11mm cable is designed to be compatible with standard seismic transmitters and proximity probes within the 3300 XL ecosystem.

Q: Why is shielding so important for these cables?

A> Motors and drives create strong electromagnetic fields. Proper shielding is critical to prevent this ambient noise from distorting the sensitive microvolt-level signals from vibration sensors.

Check below popular items for more information in Nex-Auto Technology.

| Model | Title | Link |

|---|---|---|

| 330730-040-00-CN | 3300 XL 11 mm Extension Cable | Learn More |

| 330730-040-03-00 | Extension Cable | Learn More |

| 330730-040-03-05 | ETR Extension Cable | Learn More |

| 330730-040-03-CN | Extension Cable | Learn More |

| 330730-040-10-CN | Bently Nevada Extension Cable | Learn More |

| 330730-040-10-00 | 3300 XL ETR Extension Cable | Learn More |

| 330730-040-10-05 | ETR Extension Cable | Learn More |

| 330730-040-01-00 | Extension Cable | Learn More |

| 330730-040-01-05 | 3300 XL Extension Cable | Learn More |

| 330730-040-11-00 | 3300 XL Extension Cable | Learn More |

| 330730-040-11-05 | Bently Nevada ETR Extension Cable | Learn More |

| 330730-040-11-CN | 3300 XL ETR Extension Cable | Learn More |

| 330730-040-13-CN | 3300 XL Extension Cable Bently Nevada | Learn More |

| 330730-040-12-CN | Bently Nevada ETR Extension Cable | Learn More |

| 330730-040-12-00 | Extension Cable | Learn More |

| 330730-040-12-05 | Bently Nevada ETR Extension Cable | Learn More |

| 330730-080-11-00 | Bently Nevada Extension Cable | Learn More |

| 330730-080-11-05 | 3300 XL Armored Cable | Learn More |

| 330730-080-11-CN | Bently Nevada Armored Cable | Learn More |

| 330730-080-13-00 | 3300 XL Extension Cable | Learn More |

| 330730-080-13-05 | ETR Extension Cable Bently Nevada | Learn More |

| 330730-080-12-CN | Extension Cable | Learn More |

| 330730-080-12-00 | Bently Nevada ETR Extension Cable | Learn More |

| 330730-080-12-05 | ETR Extension Cable | Learn More |

| 330730-040-02-00 | Bently Nevada Extension Cable | Learn More |