How Does the Bently Nevada 330980 Sensor Enhance Machinery Protection?

Industrial automation relies on precise monitoring to prevent costly failures. Modern plants now use advanced sensors for predictive maintenance strategies. These technologies reduce unplanned downtime by up to 45%, according to industry studies.

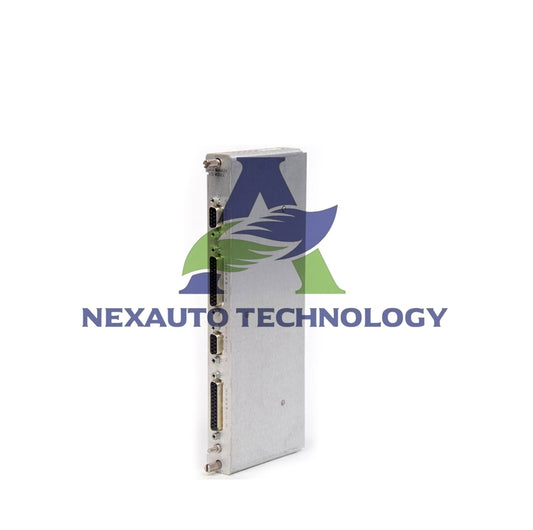

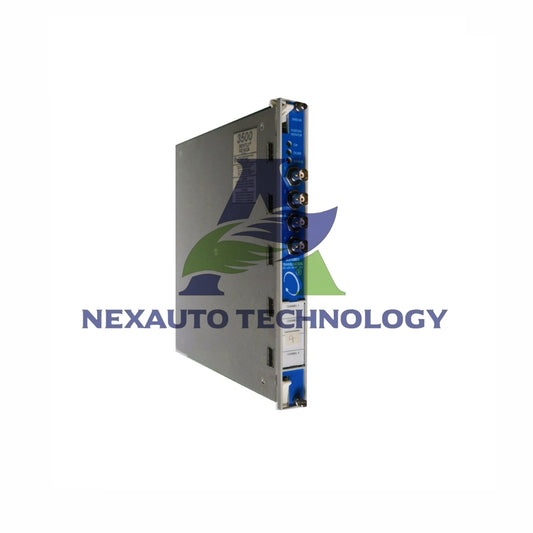

Advanced Vibration Monitoring Technology

The 330980 NSv Proximitor employs eddy-current sensing technology. This non-contact method measures shaft vibration with micron-level accuracy. As a result, operators detect mechanical issues weeks before failure occurs. Moreover, this approach eliminates sensor wear from physical contact.

Critical Position Measurement Capabilities

Beyond vibration, this sensor monitors axial position changes. It tracks rotor movement within thousandths of an inch precision. Therefore, maintenance teams can prevent catastrophic thrust bearing failures. This dual-function design reduces installation points by 40%.

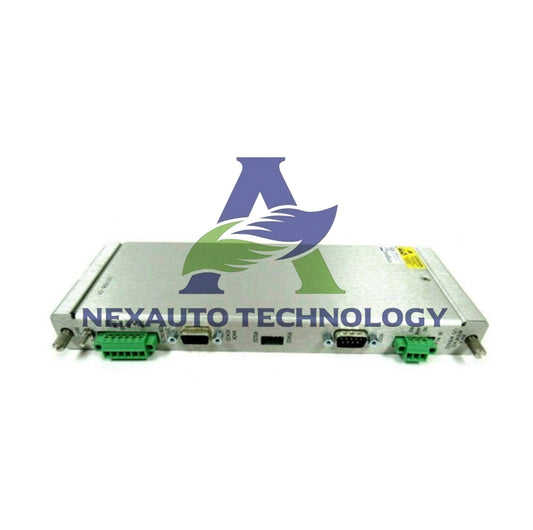

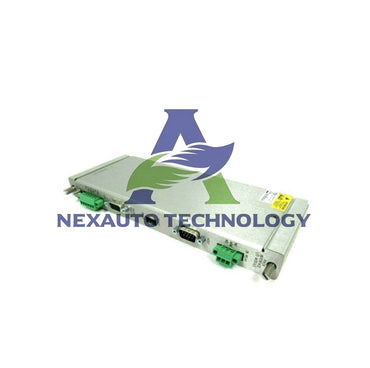

Rugged Industrial Design Features

Bently Nevada engineered this sensor for harsh environments. Its housing withstands extreme temperatures and contaminants. Additionally, electromagnetic interference protection ensures reliable data collection. These features guarantee continuous operation in demanding applications.

Practical Application Scenarios

A Midwest power generation facility implemented these sensors in 2022. They monitored six natural gas turbines operating at 3,600 RPM. The system detected bearing wear on Unit #4 fourteen days before alarm thresholds. Consequently, technicians scheduled repairs during a planned outage, preventing an estimated $350,000 in lost production.

Industry Trends and Author Insight

The industrial sector increasingly integrates sensors with IIoT platforms. In my professional assessment, the 330980's compatibility with major control systems provides lasting value. However, plants must train personnel to interpret vibration data correctly. Proper analysis transforms raw measurements into actionable maintenance decisions.

Predictive Maintenance Implementation

Successful programs combine reliable sensors with analytical software. First, install sensors on all critical machinery. Then, establish baseline vibration profiles under normal operation. Finally, set alerts at 80% of failure threshold levels. This methodology typically reduces maintenance costs by 25-30% annually.

Technical Specifications and Integration

This sensor connects directly to Bently Nevada's 3500 monitoring systems. It maintains accuracy across -30°C to 120°C operating ranges. Furthermore, its calibration remains stable for over five years of continuous service. Integration requires standard industrial cabling and mounting hardware.

FAQ: Common Technical Questions

Q: What minimum vibration level can this sensor detect?

A: It reliably measures vibrations as small as 0.1 mils (0.00254 mm).

Q: How does temperature affect measurement accuracy?

A: Built-in compensation maintains ±2% accuracy across the full temperature range.

Q: Can this sensor monitor different shaft materials?

A: Yes, but optimal performance requires carbon steel or similar ferromagnetic materials.

Q: What is the typical installation time per sensor?

A: Experienced technicians require approximately 1.5 hours for proper mounting and calibration.

Q: How often should calibration be verified?

A: Annual verification is recommended, though the sensor maintains calibration for five years.

Check below popular items for more information in Nex-Auto Technology.

| Model | Title | Link |

|---|---|---|

| 330980-70-00 | Proximitor Sensor - Bently Nevada | Learn More |

| 330980-72-00 | Proximitor Sensor - Bently Nevada | Learn More |

| 330980-72-CN | NSv Proximitor Sensor - Bently Nevada | Learn More |

| 330980-72-05 | Bently Nevada 3300 XL NSv Proximitor Sensor | Learn More |

| 330980-71-05 | 3300 XL NSv Proximitor Sensor | Learn More |

| 330980-50-05 | NSv Proximitor Sensor - Bently Nevada | Learn More |

| 330980-71-CN | Bently Nevada Proximitor Sensor | Learn More |

| 330980-70-CN | Bently Nevada NSv Proximitor Sensor | Learn More |