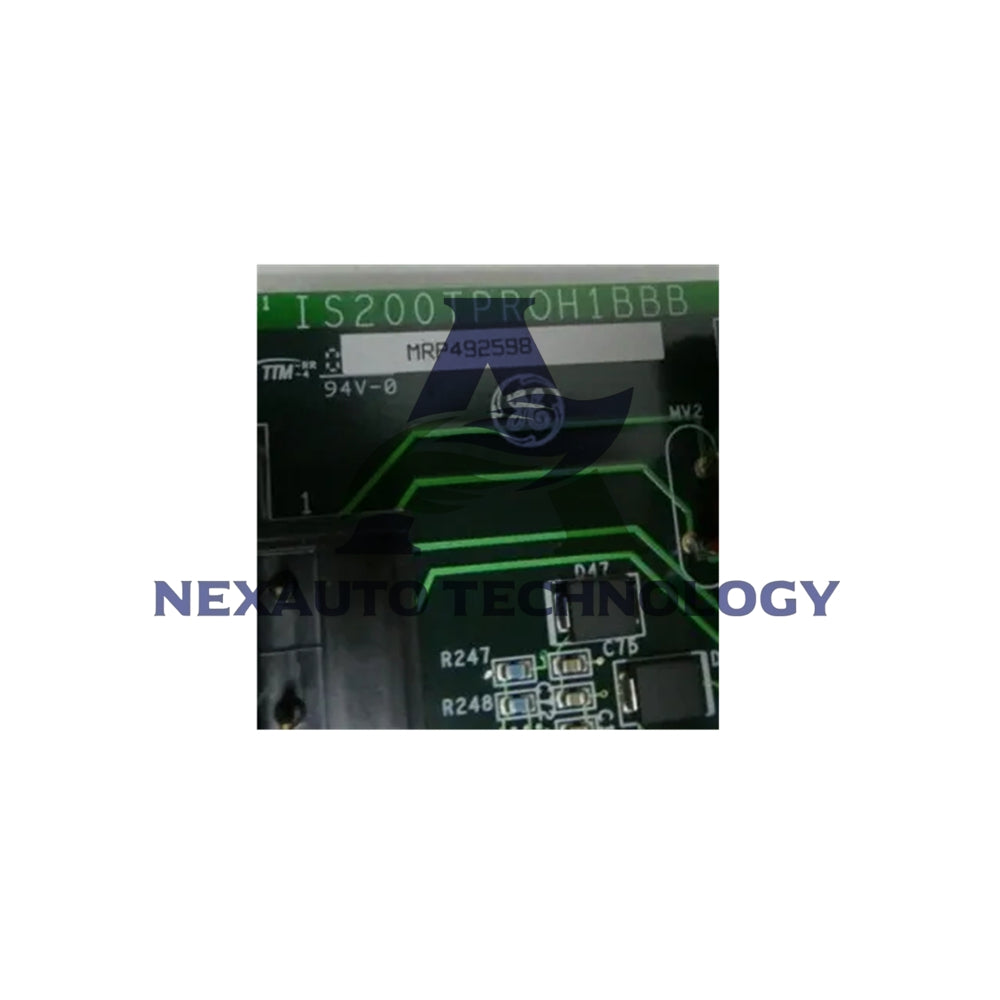

GE Overspeed Protection Board IS200TPROH1BBB

Bulk Orders & Fast Shipping

Instant 10% Discount On Winter Banks Credit/Debit Cards EMI and CreditCard

Fast & Reliable Worldwide Shipping – Ready to Dispatch from Stock

- Fast shipping

- Return Policy

- Lowest Price

- Help Center 24/7

-

Vendor:

General Electric

-

Type:

Terminal Board

- Tags Terminal board

About the Product

Critical Emergency Protection for Turbine Systems

General Electric engineered the IS200TPROH1BBB for essential safety functions. This Protection Board operates within Mark VI turbine control systems. It provides independent emergency overspeed and synchronization protection separate from primary control systems.

Core Technical Specifications

- Manufacturer & Model: General Electric IS200TPROH1BBB

- Product Type: Protection Board

- Series: Mark VI Turbine Control System

- Dimensions: 17.8 × 33.02 cm (7.0 × 13.0 inches)

- Operating Temperature: -30°C to +65°C

- Manufacturing Origin: United States

- Designed for gas and steam turbine automation

Protection System Architecture

- Triple redundant VPRO boards for maximum reliability

- Operates separately from primary turbine control system

- Provides independent emergency overspeed protection

- Manages emergency synchronization protection functions

- Source of inputs to all three VPRO boards

- Ensures safety and stability in critical situations

Emergency Trip Functions

- Controls trip solenoids via TREx modules (TREG, TREL, TRES)

- VPRO provides primary emergency trip function

- Manages up to three trip solenoids for redundancy

- TREx and TRPx terminal boards manage 125 VDC supply

- Either board can trip turbine in emergency situations

- Coordinated response to critical emergency scenarios

Signal Delivery & Monitoring

- Delivers speed signals for overspeed protection

- Provides temperature monitoring for system safety

- Supplies generator voltage data for synchronization

- Monitors bus voltage for electrical system stability

- Critical signal delivery to all three VPRO boards

- Facilitates coordinated emergency function responses

Relay Control & Management

- VPRO controls 12 relays on TREG board

- Nine relays form three groups for input voting

- Voted inputs manage the three trip solenoids

- Secondary TREG board can be driven through J4 connection

- Enhances redundancy and control capabilities

- Crucial elements in emergency response coordination

Physical Board Layout

- Two large black terminal blocks with white numbering

- 48 silver metallic terminals labeled 1 to 48

- Two red square relays with yellow components on top

- Metal Oxide Varistors (MOV) in solid red near relays

- Three black variable resistors in vertical line at upper right

- Multiple small yellow capacitors concentrated at bottom

Additional Components

- Line of small silver components in vertical row on left half

- Multiple black rectangular diodes concentrated at bottom

- Variable resistors identified with letter "R" designation

- Comprehensive electronic component arrangement

- Components range from very small to large sizes

- Organized layout for reliable operation

Cabling & Interconnection

- Intricate cabling from TPRO to VPRO and TREx boards

- Ensures proper data flow and control signal transmission

- Visual representation available for installation guidance

- Clear layout for system integration and maintenance

- Optimized connections for emergency response timing

- Reliable interconnection for critical safety functions

System Integration

- Collaborates with VPRO for complete protection system

- Forms independent emergency overspeed protection

- Provides synchronization protection capabilities

- Integrates with existing turbine control infrastructure

- Compatible with standard Mark VI system components

- Designed for seamless emergency system operation

Safety Prioritization

- Prompt and coordinated responses to emergencies

- Prioritizes safety and system stability above all

- Independent operation from primary control systems

- Multiple redundancy layers for maximum reliability

- Comprehensive emergency scenario coverage

- Designed for critical turbine protection applications

Product Availability

- Current Status: In stock for immediate shipment

- New and original General Electric component

- Complete with all necessary hardware

- Ships in protective packaging with documentation

- Ready for integration into protection systems

- Manufactured to industrial quality standards

Application Areas

- Gas turbine emergency protection systems

- Steam turbine overspeed protection

- Generator synchronization safety systems

- Industrial turbine emergency shutdown

- Critical infrastructure protection

- Redundant safety system implementations

Shipping & Delivery

- Fast shipping via FedEx, UPS, and DHL services

- Orders typically ship within 24 business hours

- International shipping available worldwide

- Complete tracking information provided

- Professional packaging ensures board protection

Frequently Asked Questions (FAQ)

What is the primary function of this board?

- The IS200TPROH1BBB provides independent emergency overspeed and synchronization protection for turbine systems.

How does it interface with other components?

- It serves as the source of inputs to triple redundant VPRO boards and controls trip solenoids via TREx modules.

What protection functions does it provide?

- Provides emergency overspeed protection, emergency stop functions, and synchronization protection capabilities.

How many relays does it control?

- VPRO controls 12 relays on the TREG board, with nine relays forming three groups for input voting.

Is this system redundant?

- Yes, it interfaces with triple redundant VPRO boards and operates separately from the primary control system for maximum safety.

What signals does it monitor?

- Monitors speed, temperature, generator voltage, and bus voltage for comprehensive protection coverage.

Quick Quotes & Info

- Quick Quotes: Receive pricing and availability fast from our dedicated customer service team.

- Delivery: Expedited, freight, and international shipping available worldwide.

- Warranty: NexAuto offers a 12-month warranty on all parts purchased from us, in addition to any manufacturer coverage.

- Returns: 30-day return policy for defective or mismatched parts, ensuring peace of mind.

- Payment: Flexible options including major credit cards, PayPal, and bank transfers.

- Custom Calibration: Provide your specifications, and we’ll handle the rest with precision.

Industrial Electrical Solutions

Comprehensive Automation Equipment for Every Facility

PLCs, HMIs, Servo Drives, Sensors, and Cables for reliable operations.

BENTLEY NEVADA

Condition Monitoring Solutions

Proximity probes, sensors, and monitoring systems to protect critical machinery.

ALLEN-BRADLEY

Industrial Automation Components

High-quality PLCs, HMIs, and I/O modules for reliable control systems.

HONEYWELL

Controllers, I/O & Interface Modules

New parts to support DCS platforms and PLC installations.

Blog posts

-

Is Vibration Monitoring Missing from Your PLC Control Strategy?

This article explores the critical integration of vibration monitoring within industrial automation systems like PLCs...

-

How Do You Perform Loop Checks Before Control System Startup?

This guide details the critical process of loop checking for industrial control systems before commissioning....

-

How Can SCADA HMI Design Boost Operator Efficiency?

This article provides a comprehensive guide to designing SCADA Human-Machine Interfaces (HMIs) that maximize operator...