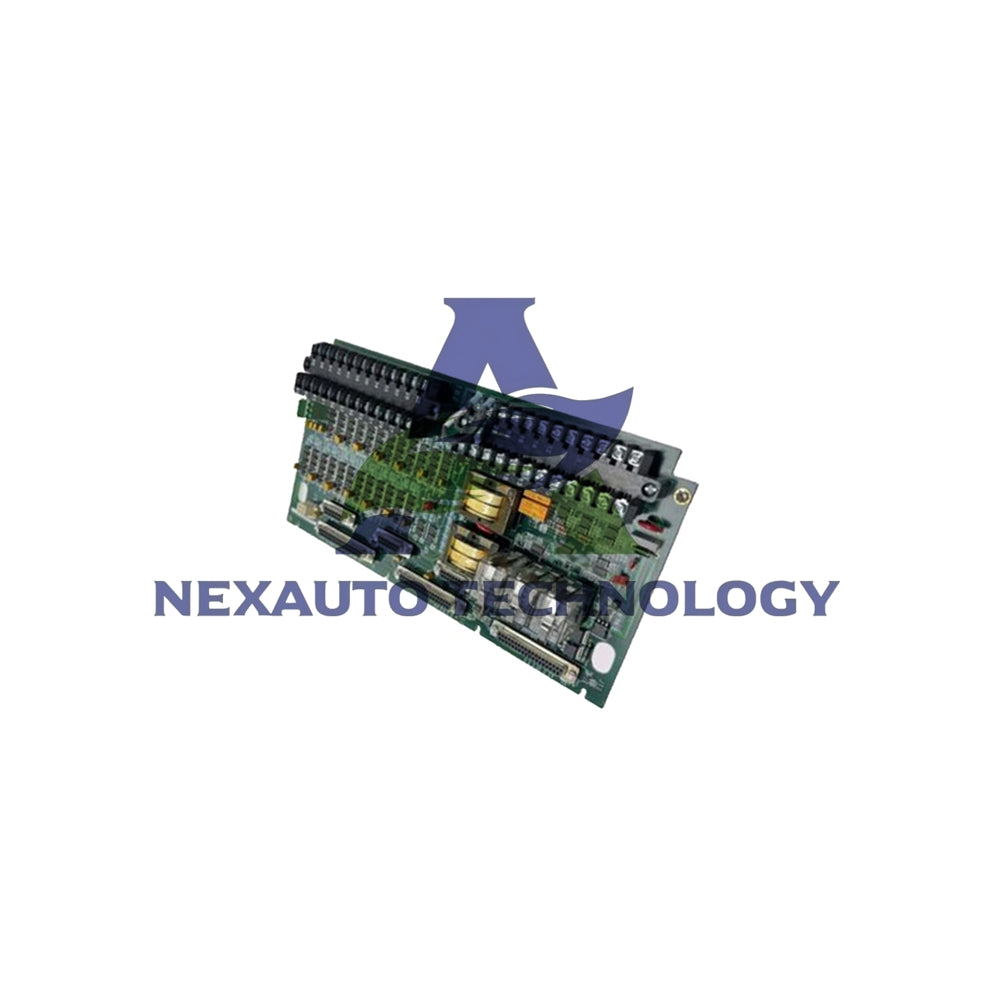

Mark VI Turbine Terminal Board IS200TTURH1BCC GE

Bulk Orders & Fast Shipping

Instant 10% Discount On Winter Banks Credit/Debit Cards EMI and CreditCard

Fast & Reliable Worldwide Shipping – Ready to Dispatch from Stock

- Fast shipping

- Return Policy

- Lowest Price

- Help Center 24/7

-

Vendor:

General Electric

-

Type:

Terminal Board

- Tags Terminal board

About the Product

Comprehensive Turbine Protection and Synchronization

General Electric engineered the IS200TTURH1BCC for critical turbine operations. This Primary Protection Input Board operates within Mark VI Speedtronic systems. It provides essential monitoring and control functions for safe and reliable turbine operation.

Core Technical Specifications

- Manufacturer & Model: General Electric IS200TTURH1BCC

- Product Type: Primary Protection Input Board

- Series: Mark VI Speedtronic System

- Dimensions: 33.0 × 17.8 cm (13.0 × 7.0 inches)

- Breaker Output: 5A at 125 VDC for generator coil

- Operating Temperature: -30°C to +65°C

- Technology: Surface-mount construction

Speed Measurement System

- Twelve passive pulse rate devices for turbine speed sensing

- Senses toothed wheel rotation for accurate speed measurement

- Pulse Rate Range: 2 Hz to 20 kHz operational frequency

- Measurement Accuracy: 0.05% of reading precision

- Speed signal cable connects via JR5 connector

- Critical data for turbine control and protection systems

Main Breaker Control System

- Three coordinated relays: K25, K25P, and K25A

- All three relays must close to provide 125 VDC power

- Controls main breaker 52G closure for generator synchronization

- Power Supply: Nominal 125 VDC to breaker coil

- Output Rating: 5A at 125 VDC generator breaker coil

- Essential for automatic generator synchronization

Voltage Monitoring Capabilities

- Monitors generator voltage output via potential transformers

- Tracks bus voltage levels in electrical distribution system

- Two single-phase PTs with 115 V RMS nominal output

- Loading: Less than 3 VA per input for minimal impact

- Sync Range: 75 to 130 V RMS for synchronization

- Magnetically isolated with 1,500 V RMS safety barrier

Signal Connectivity & Configuration

- Speed Signals: JR5 connector for VTUR connection

- Other Signals: JR1 connector for additional signals

- TMR Systems: JR5, JS5, JT5, JR1, JS1, JT1 connectors

- Two jumper switches for simplex/TMR configuration

- Jumpers JP1 and JP2 select SMX or TMR relay drivers

- TB3 terminal block for optional TTL connections

Installation & Wiring

- Two I/O terminal blocks (TB1, TB2) with 24 terminals each

- Accepts wires up to #12 AWG for reliable connections

- Each block secured with two screws for stability

- Shield termination strips adjacent to each terminal block

- Connected to chassis ground for proper shielding

- Magnetic pickups, shaft pickups, and potential transformers

Cable & Wiring Specifications

- Voltage Sensors: Up to 1,000 ft cable length supported

- Recommended Wiring: 18 AWG for optimal performance

- Proper grounding and shielding techniques required

- Minimizes electromagnetic interference (EMI)

- Maintains signal integrity over long distances

- Safe insulation from other system components

Hardware Components

- Relays for breaker control and protection functions

- Transformers for voltage measurement and isolation

- Plug connectors and D-shell connectors for interfacing

- Male and female connectors along board edges

- Two terminal strips with screw connectors

- Variable resistors, traditional resistors, capacitors, diodes

System Configuration Options

- Simplex Systems: JR5 and JR1 connectors only

- TMR Systems: All six connectors for redundancy

- Jumper-selectable for operational mode

- Compatible with various turbine control configurations

- Backwards compatible design features

- Flexible integration into existing systems

Shaft Monitoring

- Processes shaft voltage sensor inputs

- Monitors shaft current measurements

- Measures induced shaft voltage and current

- Provides comprehensive turbine health data

- Enables early detection of potential issues

- Integrates with overall protection system

Product Availability

- Current Status: In stock for immediate shipment

- New and original General Electric component

- Manufactured in the United States

- Complete with all necessary hardware

- Ships in protective packaging with documentation

- Ready for integration into turbine control systems

Commissioning & Testing

- Test and calibrate all voltage sensors after installation

- Verify synchronization capabilities within specified range

- Monitor voltage fluctuations during synchronization

- Test all relay operations and timing sequences

- Validate speed measurement accuracy

- Confirm proper grounding and shielding effectiveness

Shipping & Delivery

- Fast shipping via FedEx, UPS, and DHL services

- Orders typically ship within 24 business hours

- International shipping available worldwide

- Complete tracking information provided

- Professional packaging ensures board protection

Frequently Asked Questions (FAQ)

What is the main function of this board?

- The IS200TTURH1BCC provides turbine protection through speed monitoring, voltage measurement, and main breaker control for generator synchronization.

How many speed sensors does it support?

- It interfaces with twelve passive pulse rate devices for accurate turbine speed measurement and protection.

What relays control the main breaker?

- Three relays (K25, K25P, K25A) must all close to provide 125 VDC power for main breaker 52G operation.

What voltage monitoring capabilities are included?

- Monitors generator and bus voltage via potential transformers with 115 V RMS nominal output and 1,500 V RMS isolation.

How is the board configured for different systems?

- Uses jumper switches to select between simplex or Triple Modular Redundant (TMR) system configurations.

What cable lengths are supported for sensors?

- Supports cable lengths up to 1,000 feet for voltage sensors, with 18 AWG wiring recommended for optimal performance.

Quick Quotes & Info

- Quick Quotes: Receive pricing and availability fast from our dedicated customer service team.

- Delivery: Expedited, freight, and international shipping available worldwide.

- Warranty: NexAuto offers a 12-month warranty on all parts purchased from us, in addition to any manufacturer coverage.

- Returns: 30-day return policy for defective or mismatched parts, ensuring peace of mind.

- Payment: Flexible options including major credit cards, PayPal, and bank transfers.

- Custom Calibration: Provide your specifications, and we’ll handle the rest with precision.

Industrial Electrical Solutions

Comprehensive Automation Equipment for Every Facility

PLCs, HMIs, Servo Drives, Sensors, and Cables for reliable operations.

BENTLEY NEVADA

Condition Monitoring Solutions

Proximity probes, sensors, and monitoring systems to protect critical machinery.

ALLEN-BRADLEY

Industrial Automation Components

High-quality PLCs, HMIs, and I/O modules for reliable control systems.

HONEYWELL

Controllers, I/O & Interface Modules

New parts to support DCS platforms and PLC installations.

Blog posts

-

Is Vibration Monitoring Missing from Your PLC Control Strategy?

This article explores the critical integration of vibration monitoring within industrial automation systems like PLCs...

-

How Do You Perform Loop Checks Before Control System Startup?

This guide details the critical process of loop checking for industrial control systems before commissioning....

-

How Can SCADA HMI Design Boost Operator Efficiency?

This article provides a comprehensive guide to designing SCADA Human-Machine Interfaces (HMIs) that maximize operator...