A Practical Guide to Getting Started with the Allen-Bradley PowerFlex 40 AC Drive

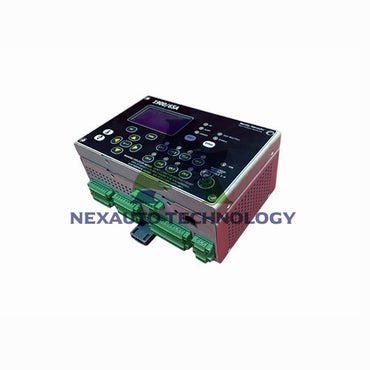

For professionals in industrial automation, implementing a new drive system requires both precision and efficiency. The Allen-Bradley PowerFlex 40 Adjustable Frequency AC Drive (covering firmware versions FRN 5.xx through 6.xx) is a cornerstone for reliable motor control. This article provides a clear, actionable overview of its initial setup, drawing from official documentation to help qualified personnel kickstart their projects safely and effectively.

Streamlining Your PowerFlex 40 Drive Installation

Proper installation forms the foundation for optimal drive performance. First, ensure the physical environment meets specifications for temperature and clearance. Next, follow all electrical safety procedures when connecting power and motor leads. Correctly sizing the branch circuit protection is also critical. Moreover, verifying a secure ground connection will prevent potential faults and ensure operational safety from the very beginning.

Power-Up and Basic Startup Procedures

After installation, the initial startup phase begins. Applying power allows the drive to perform its internal diagnostics. You can then use the integral keypad to configure essential motor parameters, such as nameplate voltage and current. This step is vital for achieving efficient motor operation. Therefore, always double-check these values against your specific motor's data plate to ensure accuracy and prevent damage.

Essential Programming Parameters for Core Functions

Programming the PowerFlex 40 drive unlocks its control capabilities. Key parameters manage acceleration and deceleration rates, providing smooth starts and stops. Furthermore, setting minimum and maximum output frequency defines the motor's operational speed range. The drive also offers multiple control source options, allowing selection between the keypad, terminal inputs, or a network. Consequently, tailoring these settings aligns the drive precisely with your application's needs.

Critical Safety and Professional Guidance Notes

This guide summarizes basic procedures but has crucial limitations. The information provided does not replace the official PowerFlex 40 User Manual (Publication 22B-UM001). It is intended solely for qualified drive service personnel with relevant training. For comprehensive details on EMC compliance, advanced application considerations, and all safety precautions, you must consult the full manual. Ignoring this can lead to equipment failure or safety hazards.

Industry Trend: The Shift to Simplified Automation Solutions

The industrial automation sector increasingly values solutions that balance capability with simplicity. The PowerFlex 40 series represents this trend perfectly - offering robust motor control without overwhelming complexity. In my professional assessment, this approach reduces training time and minimizes implementation errors. However, true efficiency comes from pairing this simplicity with thorough documentation review, particularly for applications involving multiple drives or complex control systems.

Application Case Study: HVAC Fan System Optimization

A commercial building's HVAC system required precise fan speed control to maintain air quality while reducing energy consumption. Engineers installed a PowerFlex 40 drive (FRN 6.xx) to control a 10 HP fan motor. They programmed the drive to respond to a 4-20mA signal from a building pressure sensor. Key parameters included:

- Acceleration Time: 15 seconds

- Deceleration Time: 20 seconds

- Minimum Frequency: 15 Hz

- Maximum Frequency: 60 Hz

The result was a 32% reduction in energy consumption and more stable building pressure control. The drive's built-in PID functionality allowed seamless integration without additional controllers.

Practical Solution Scenario: Water Treatment Pump Control

In a municipal water treatment plant, chemical dosing pumps required precise flow control. The solution involved PowerFlex 40 drives configured for:

- Motor: 5 HP, 460V, 3-phase

- Control Method: Analog input (0-10V) from flow meter

- Preset Speeds: 30%, 60%, 100% for different treatment stages

- Current Limit: 110% for temporary overload conditions

The implementation achieved ±2% flow accuracy and reduced mechanical stress on pump components. The drive's automatic restart feature ensured continuous operation after brief power interruptions.

Author's Professional Recommendation

Based on field experience, I strongly recommend creating a parameter checklist specific to your application before beginning PowerFlex 40 programming. Document all changes from default values, especially safety-related parameters. This practice not only streamlines commissioning but also simplifies troubleshooting and future maintenance. Remember that while the Quick Start gets you running, the full manual contains crucial information about heat dissipation, braking resistor requirements, and network communication options that can significantly impact long-term performance.

Future-Proofing Your Motor Control Strategy

As industrial facilities move toward IIoT connectivity, consider how the PowerFlex 40 fits into broader automation architectures. While this drive model focuses on standalone or basic networked operation, planning for future integration with plant-wide control systems is wise. Ensure your installation includes proper documentation and parameter backups to facilitate potential future upgrades or integration with more advanced Rockwell Automation ecosystems.

Frequently Asked Questions (FAQ)

Q1: Who should use this Quick Start guide for the PowerFlex 40?

A1: This guide is intended exclusively for qualified industrial drive service personnel who are trained in working with electrical and control systems.

Q2: Does this guide replace the full User Manual?

A2: No, it does not. This guide summarizes basic steps. You must refer to the PowerFlex 40 User Manual (22B-UM001) for complete safety, EMC, and detailed application information.

Q3: What firmware versions does this guide apply to?

A3: The procedures outlined are relevant for drives with Firmware Revision Numbers (FRN) 5.xx through 6.xx.

Q4: What is the most critical step during PowerFlex 40 startup?

A4: Accurately entering the motor's nameplate data (voltage, current, frequency) is crucial for ensuring efficient operation and preventing motor damage.

Q5: Can I use this guide for complex application commissioning?

A5: No. This guide covers basic installation and startup. Complex applications involving advanced programming, networking, or specific safety functions require the detailed instructions in the full User Manual.

Check below popular items for more information in Nex-Auto Technology.

| Model | Title | Link |

|---|---|---|

| 22B-B012C104 | Allen Bradley AC Drive | Learn More |

| 22B-B012H204 | PowerFlex 40 2.2 kW AC Drive | Learn More |

| 22B-B017H204 | PowerFlex 40 AC Drive - Allen Bradley | Learn More |

| 22B-B024H204 | PowerFlex 40 AC Drive | Learn More |

| 22B-B033F104 | PowerFlex 40 Adjustable Frequency Drive | Learn More |

| 22B-B033N104 | PowerFlex 40 Variable Frequency Drive | Learn More |

| 22B-B2P3H204 | PowerFlex 40 0.4 kW AC Drive | Learn More |

| 22B-B2P3N104 | PowerFlex 40 Variable Frequency Drive | Learn More |

| 22B-B5P0F104 | PowerFlex 40 0.75 kW AC Drive | Learn More |

| 22B-B5P0H204 | Allen Bradley AC Drive | Learn More |

| 22B-B8P0N104 | PowerFlex 40 Adjustable Frequency Drive | Learn More |

| 22B-CCB | Communication Adapter Cover - Allen Bradley | Learn More |

| 22B-CCC | Allen Bradley Communication Adapter Cover | Learn More |

| 22B-D010C104 | PowerFlex 40 Adjustable Frequency AC Drive | Learn More |

| 22B-D010F104 | Allen Bradley AC Drive - PowerFlex 40 | Learn More |

| 22B-D010H204 | PowerFlex 40 AC Drive | Learn More |

| 22B-D012F104 | Allen Bradley PowerFlex 40 AC Drive | Learn More |

| 22B-D012H204 | AC Drive 5.5 kW 7.5 HP | Learn More |

| 22B-D1P4C104 | PowerFlex 40 Adjustable Frequency AC Drive | Learn More |

| 22B-D1P4F104 | PowerFlex 40 0.4 kW AC Drive | Learn More |

| 22B-D1P4H204 | AC Drive 0.4 kW 0.5 HP | Learn More |

| 22B-D6P0F104 | AC Drive 2.2 kW 3 HP | Learn More |