How to Protect Critical Machinery in Extreme Heat: A Guide to Reliable Monitoring

Industrial processes involving extreme temperatures pose a constant threat to machinery health. When standard monitoring equipment fails under thermal stress, plants face data blackouts and unexpected breakdowns. This article examines a proven monitoring solution designed for these harsh conditions, essential for any modern predictive maintenance strategy.

The Unforgiving Reality of High-Temperature Environments

Assets like gas turbines and high-pressure compressors often have casing temperatures above 200°C. Consequently, ordinary sensors and wiring in these areas degrade rapidly. This leads to unreliable data, forcing maintenance teams to make critical decisions blindly. The potential cost? Catastrophic failures and downtime costing hundreds of thousands daily.

Engineered Resilience for Machinery Protection

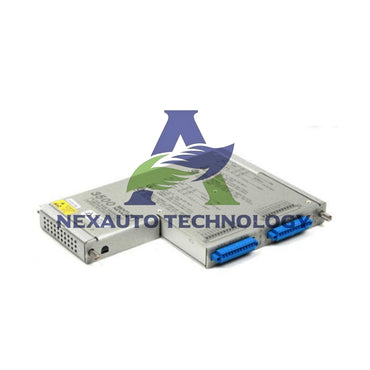

The Bently Nevada 3300 XL system is a benchmark in industrial machinery safeguarding. It delivers continuous, precise measurement of shaft vibration and position. Moreover, its design prioritizes signal stability in demanding settings, making it a cornerstone for condition-based maintenance programs within industrial automation.

Technical Edge in Hostile Conditions

This system employs specialized probes and armored cables rated for ambient temperatures up to 120°C. Its oscillator-demodulator technology maintains signal integrity over long distances, exceeding 300 meters. As a result, control systems receive the accurate, real-time data necessary to protect multi-million dollar capital assets.

Simplifying Integration with Factory Control Systems

Connecting the 3300 XL to existing factory automation architecture is straightforward. The system provides standard 4-20 mA and voltage signals compatible with major PLC and DCS platforms. Therefore, it enables smooth data flow to control rooms and asset management software, enhancing overall plant intelligence for Industry 4.0.

Solutions in Action: Gas Turbine Stability

A major power generation facility experienced repeated, unexplained trips on a critical gas turbine. Erratic vibration data from a high-temperature bearing location was the culprit. After installing the high-temperature 3300 XL system, data stabilized, revealing a bearing oil whirl condition. This insight allowed for a planned repair, averting a forced outage estimated at over $420,000 per day and potential rotor damage costing $2 million.

Solutions in Action: Compressor Reliability in Chemicals

An ethylene plant's synthesis gas compressor, vital to operations, suffered from frequent probe failures in a hot discharge section. Probes lasted less than a year. Switching to the 3300 XL system provided over three years of continuous operation. The reliable data tracked a gradual vibration increase, diagnosing rotor fouling. An online wash prevented a full shutdown, saving an estimated $1.8 million in lost production.

Solutions in Action: Boiler Feed Pump Predictive Insight

A refinery monitored boiler feed pumps where temperatures neared 180°C. Standard sensors provided drifting baselines. Upgrading to high-temperature probes with the 3300 XL framework provided stable readings. This data identified a slow growth in axial position variation, predicting a thrust bearing wear issue 4 months in advance. The repair was scheduled with routine maintenance, avoiding a $750,000 unplanned outage.

Expert Perspective: The Data Bedrock for Digital Twins

The shift towards predictive maintenance relies on trustworthy data. As noted by specialists at NexAuto Technology Limited, systems like the 3300 XL form the essential data acquisition layer. "Advanced analytics and AI models are only as good as their input data," states our analysis. "Investing in robust edge sensing is the non-negotiable first step for a digital transformation."

Industry Shift: Merging Operational Data with IT Analytics

A significant trend is the direct flow of high-fidelity vibration data into cloud analytics platforms. This convergence of OT and IT enables fleet-wide performance benchmarking. However, this trend reinforces the absolute need for trusted, accurate data sources at the machine edge—a core strength of the 3300 XL system.

Implementation Advice: A Strategic, Phased Plan

For plants planning an upgrade, a risk-based approach is wise. First, identify the most critical machinery operating in the hottest zones. A thermal survey can map exact high-temperature points. Then, initiate a phased rollout starting with these high-risk assets. Collaboration with a skilled integrator is key for proper calibration and commissioning.

Securing Operational Excellence Through Proactive Monitoring

In high-heat industrial applications, reliable data is paramount. The Bently Nevada 3300 XL proximity monitoring system delivers the durability and accuracy needed to safeguard vital equipment. By enabling true predictive maintenance, it significantly reduces unplanned downtime and delivers a compelling return on investment, underpinning modern plant safety and efficiency.

Frequently Asked Questions (FAQ)

Why is Bently Nevada often specified for critical applications?

Bently Nevada has built a multi-decade reputation for engineering exceptionally reliable and robust monitoring systems, making it the preferred choice for high-criticality assets in sectors like power generation and oil & gas.

Can this system integrate with our current CMMS software?

Yes. Its standard industrial outputs allow for straightforward integration with major Enterprise Asset Management (EAM) and Computerized Maintenance Management System (CMMS) platforms, feeding vital data directly into your workflow.

What justifies the investment in a specialized high-temperature system?

The Return on Investment is typically realized by preventing a single forced outage. For essential machinery, avoiding one unplanned shutdown—often costing between $200,000 to $1,000,000+ per day—easily validates the capital expenditure.

How does this aid in meeting industry standards?

It supports compliance with key machinery safety and reliability standards such as API 670 for protection systems and ISO 13373 for condition monitoring and diagnostics.

Is remote, centralized monitoring supported?

Absolutely. When incorporated into a plant's network, data from the 3300 XL system can be accessed remotely for expert diagnostics and centralized condition monitoring programs, facilitating support from anywhere.

How does the system handle long-distance cable runs?

The system's design is optimized for extended cable lengths without signal loss. This ensures accurate readings even when monitoring racks are located a significant distance from the machine, which is common in large plant layouts.

What's the typical lifespan of the high-temperature components?

While lifespan depends on the specific environment, high-temperature probes and armored cables from this system are engineered for longevity, often operating reliably for multiple years in conditions where standard components fail annually.

Partner: AutoNex Controls Limited

© 2026 NexAuto Technology Limited. All rights reserved.

Original Source: https://www.nex-auto.com/

Contact: sales@nex-auto.com | +86 153 9242 9628