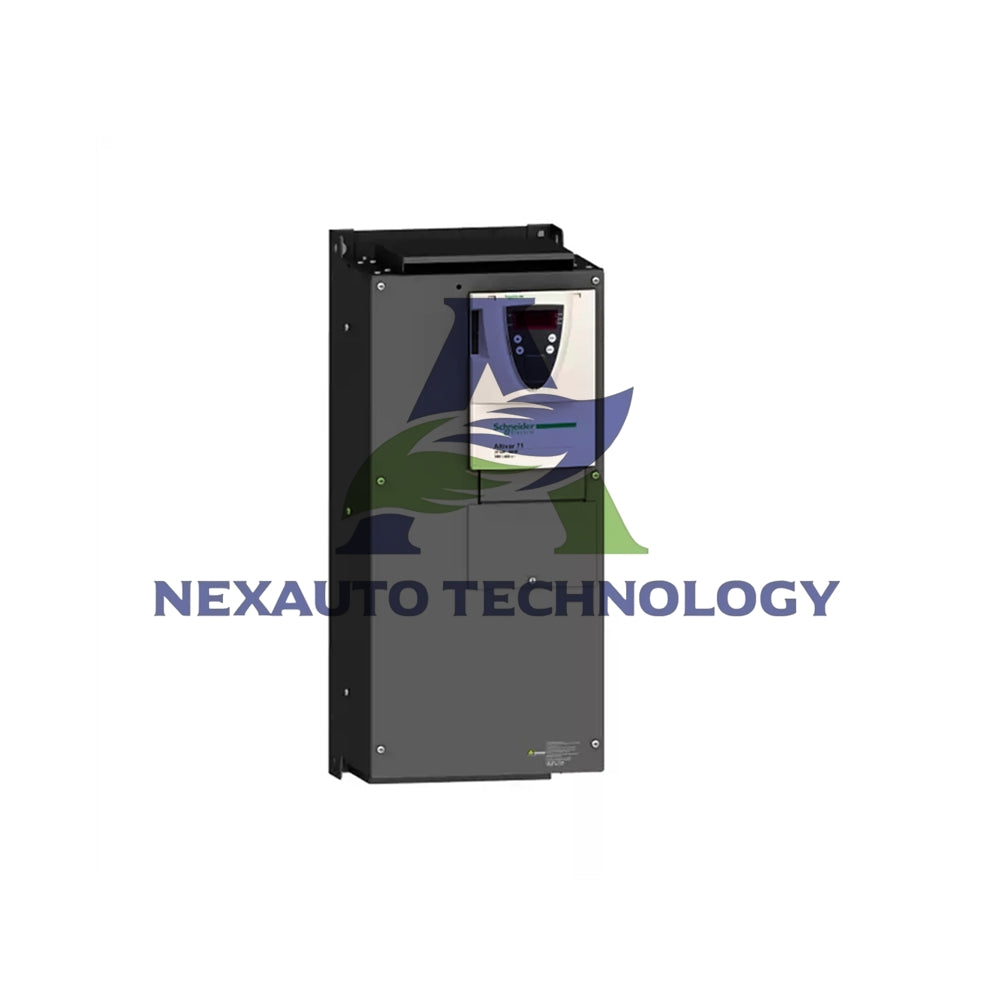

ATV61HC11N4 Altivar 61 Drive | Schneider Electric

Bulk Orders & Fast Shipping

Instant 10% Discount On Winter Banks Credit/Debit Cards EMI and CreditCard

Fast & Reliable Worldwide Shipping – Ready to Dispatch from Stock

- Fast shipping

- Return Policy

- Lowest Price

- Help Center 24/7

-

Vendor:

Schneider

-

Type:

Variable Speed Drive

- Tags Variable speed drive

About the Product

Schneider Electric ATV61HC11N4 Technical Specifications

Product Identification

- Brand & Model: Schneider Electric ATV61HC11N4

- Product Type: Variable Speed Drive, Altivar 61 Series

- Power Rating: 110 kW (150 HP) 3-phase

- Supply Voltage: 380-480V AC 3-phase

- Protection Ratings: IP00 to IP54 (varies by area)

Electrical Specifications

- Motor Power: 110 kW (150 HP) 3-phase

- Line Current: 202 A at 380V / 168 A at 480V

- Continuous Output Current: 215 A at 2.5 kHz

- Apparent Power: 133 kVA at 380V

- Output Frequency: 0.1-500 Hz

- Nominal Switching Frequency: 2.5 kHz

- Switching Frequency Range: 2-8 kHz adjustable

- EMC Filter: Level 3 integrated

Control & Communication

- Communication Protocols: Modbus, CANopen

- Transmission Rates: Modbus: 4.8-38.4 kbps; CANopen: 20-1000 kbps

- Interfaces: 2 × RJ45 (Modbus), Male SUB-D 9 (CANopen)

- Option Cards: Profibus DP, Ethernet/IP, DeviceNet, Modbus TCP, etc.

- Control Modes: V/F (2/5-point), Flux Vector, Energy Saving, Synchronous Vector

- Analog Inputs: 2 (AI1: +/-10V differential, AI2: 0-10V/0-20mA)

- Analog Output: 1 (AO1: 0-10V/0-20mA)

- Discrete Inputs: 7 programmable

- Relay Outputs: 2 configurable

Mechanical & Physical

- Dimensions: 320 × 920 × 377 mm (W × H × D)

- Weight: 84 kg (185.2 lb)

- Mounting: With heat sink, vertical ±10°

- Electrical Connections: Power: 2×100 mm²; Control: 2.5 mm²

- Assembly Style: With heat sink

- Noise Level: 60.5 dB

Environmental & Certifications

- Operating Temperature: -10°C to +45°C (no derating), 45-60°C with derating

- Operating Altitude: ≤1000m without derating, 1000-3000m with 1%/100m derating

- Relative Humidity: 5-95% non-condensing

- Certifications: CE, CSA, UL, GOST, NOM, DNV, C-Tick

- Standards: EN/IEC 61800-3, EN/IEC 61800-5-1, IEC 60721-3-3

- Application: Pumping and ventilation machinery

Ordering & Packaging

- Category: US1CP4C22138

- Discount Schedule: CP4C

- GTIN: 3389118080614

- Package Type: PCE, 1 unit

- Package Dimensions: 122.5 × 41.0 × 53.0 cm

- Package Weight: 115 kg (253.5 lb)

Contact Information Inquiries: sales@nex-auto.com , +86 153 9242 9628

Partner AutoNex Controls Limited: https://www.autonexcontrol.com/

© 2025 NexAuto Technology Limited. All rights reserved.

Original Source: https://www.nex-auto.com/

Quick Quotes & Info

- Quick Quotes: Receive pricing and availability fast from our dedicated customer service team.

- Delivery: Expedited, freight, and international shipping available worldwide.

- Warranty: NexAuto offers a 12-month warranty on all parts purchased from us, in addition to any manufacturer coverage.

- Returns: 30-day return policy for defective or mismatched parts, ensuring peace of mind.

- Payment: Flexible options including major credit cards, PayPal, and bank transfers.

- Custom Calibration: Provide your specifications, and we’ll handle the rest with precision.

Industrial Electrical Solutions

Comprehensive Automation Equipment for Every Facility

PLCs, HMIs, Servo Drives, Sensors, and Cables for reliable operations.

BENTLEY NEVADA

Condition Monitoring Solutions

Proximity probes, sensors, and monitoring systems to protect critical machinery.

ALLEN-BRADLEY

Industrial Automation Components

High-quality PLCs, HMIs, and I/O modules for reliable control systems.

HONEYWELL

Controllers, I/O & Interface Modules

New parts to support DCS platforms and PLC installations.

Blog posts

-

How to Connect Machine Vibration Data to Your PLC or DCS?

This guide outlines the critical vibration, spectrum, and process data to integrate from Bently Nevada...

-

Can Vibration Analysis Prevent DCS Process Alarms?

This article explains how integrating Bently Nevada vibration monitoring data with PLC/DCS control systems enables...

-

Why Is Vibration Monitoring Critical for PLC and DCS Systems?

This article explains the critical role of dedicated vibration monitoring in industrial facilities managed by...