Is Your Control System Leaving Your Machinery Unprotected?

Modern Distributed Control Systems (DCS) deliver exceptional process oversight. However, a critical vulnerability remains for the physical health of equipment. This article explains how merging machine condition monitoring with control systems creates a robust, predictive protection strategy.

The Hidden Risk in Modern Automation

DCS and PLC networks expertly manage process variables like pressure and temperature. However, they typically cannot detect mechanical wear such as bearing deterioration or shaft imbalance. This oversight is a leading cause of costly, unscheduled downtime in industrial facilities.

Mechanical Health: The Critical Data Layer

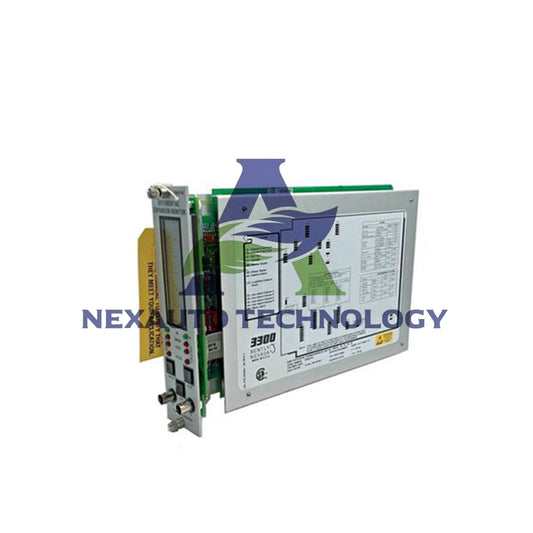

Specialized monitoring systems from providers like Bently Nevada (Baker Hughes) provide this missing intelligence. These systems measure key parameters including vibration, position, and temperature. Therefore, they offer a direct view into the physical condition of critical assets like turbines and compressors.

The Strategic Advantage of System Integration

Forward-thinking operations now integrate condition data directly into their primary DCS or SCADA screens. Moreover, this creates a unified operational awareness. Personnel can now see process performance and machine health together, enabling truly informed decision-making.

Industry Insight: The Predictive Maintenance Imperative

The industrial trend is decisively moving from preventive to predictive maintenance. In my analysis, data integration is the key enabler. I recommend treating vibration and temperature trends with the same operational priority as process alarms to build genuine resilience.

Application Case: Chemical Plant Compressor Reliability

A major chemical facility experienced repeated failures on a centrifugal synthesis gas compressor. Each event caused over 48 hours of downtime, costing approximately $125,000 per incident. After integrating Bently Nevada’s 3500 system data into their Yokogawa DCS, engineers set alert thresholds on vibration velocity and bearing temperature. Consequently, they detected a developing lubrication issue 17 days before failure. The plant performed a planned intervention during a minor process window, avoiding a full shutdown. This single event saved an estimated $250,000, and annual downtime was reduced by 80%.

Solution Scenario: Power Generation Turbine Protection

A combined-cycle power plant integrated GE Bently Nevada’s System 1* software with their Emerson Ovation DCS. The goal was to protect a critical gas turbine. Real-time monitoring of radial vibration and axial position was displayed alongside fuel flow and exhaust temperature. During a load change, operators noticed a slight but steady rise in vibration preceding a DCS process alarm. This early warning, based on a 15% increase from baseline, allowed them to stabilize operation and schedule an inspection. The inspection revealed early-stage blade fouling. Cleaning during a planned outage prevented potential forced outage costs exceeding $500,000.

Practical Implementation for Engineers

Successful integration requires careful planning. Start with high-impact assets where downtime costs exceed $10,000 per hour. Ensure network compatibility; MODBUS TCP and OPC UA are common protocols. Furthermore, develop clear procedures so operators understand how to respond to a combined process-mechanical alarm.

Concluding Analysis: Building a Holistic Defense

No control system alone can fully protect capital-intensive machinery. Adding a layer of mechanical health intelligence is essential for modern operations. This integrated approach not only prevents catastrophic failures but also optimizes maintenance spending and extends total asset life.

Frequently Asked Questions (FAQ)

Q1: What's the main operational benefit of this integration?

A: It enables predictive maintenance, moving from scheduled repairs to interventions based on actual asset condition, dramatically reducing unplanned downtime.

Q2: Will we need to replace our existing DCS hardware?

A> Almost never. Integration occurs at the software and network level using standard industrial communication protocols, preserving your current control system investment.

Q3: Which machines offer the best return on monitoring investment?

A: Prioritize assets with high replacement costs, long lead times, or a history of failures. Large compressors, turbines, and critical pumps are prime candidates.

Q4: How does this affect our maintenance budget?

A: It typically reallocates spending from reactive emergency repairs to planned, condition-based tasks. Overall costs often decrease by 20-30% while reliability improves.

Q5: Is the data reliable enough for automated shutdowns?

A: For critical protection (e.g., turbine overspeed), dedicated machinery monitoring systems provide hardened, reliable trips. For advisory alerts, integrated DCS data is excellent for operator guidance and planning.

Check below popular items for more information in Nex-Auto Technology.