From Reactive Checks to Proactive Protection: Why You Must Automate Vibration Monitoring

Manual vibration surveys have long been a cornerstone of machinery health assessment. However, in our current era of data-centric industrial operations, this method reveals considerable drawbacks. Sporadic manual measurements often fail to capture fleeting yet critical failure events. This process also drains extensive technician hours and can introduce inconsistencies. Consequently, shifting to an automated, continuous monitoring strategy is essential for predictive integrity and operational superiority.

The Inherent Shortcomings of Manual Vibration Routes

Route-based data collection offers only snapshots in time. Technicians might gather readings monthly, missing fault progression between intervals. This approach frequently overlooks vital transient states like machine startup. Data quality can also fluctuate with technician skill and probe placement. As a result, manual programs deliver a reactive and fragmented view of asset health, increasing the risk of sudden breakdowns and expensive emergency repairs.

The Proactive Advantage of Continuous Monitoring Systems

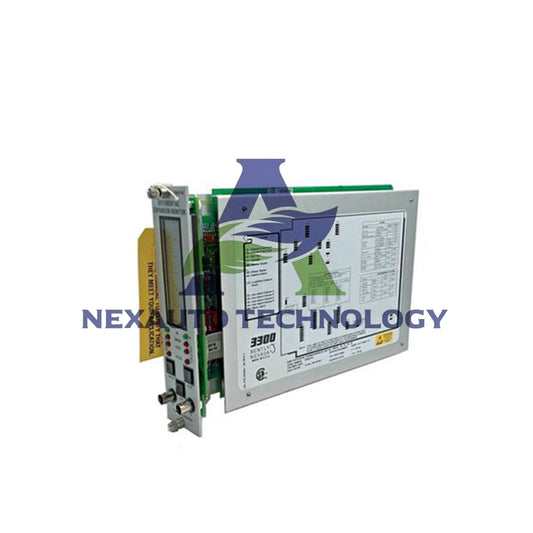

Automated condition monitoring delivers a constant flow of precise machine health information. Permanent transducers, such as Bently Nevada's 3300 XL series, gather data around the clock. This system records every operational detail, from steady-state running to process upsets. Therefore, maintenance and operations teams achieve real-time awareness of asset behavior. This shift facilitates a proactive upkeep philosophy, where anomalies are detected and corrected well before a severe malfunction happens.

Unlocking Value: Merging Vibration Data with Your Control System

The full potential of automation is realized through integration. Contemporary monitoring frameworks, like the Bently Nevada 3500 Series, are engineered to interface directly with Distributed Control Systems (DCS) including Emerson DeltaV or Honeywell Experion. This linkage commonly employs universal protocols like Modbus TCP/IP or OPC UA. Hence, vital vibration metrics stream into the primary operator console. Control room staff now see machine wellness parameters adjacent to flow, temperature, and pressure readings, consolidating their operational view.

Measurable Gains from a Centralized Monitoring Approach

Blending vibration analytics into the DCS yields concrete operational benefits. Firstly, it allows for real-time alerts based on configurable vibration limits, enabling immediate operator action. Secondly, it creates a long-term data history for performance analysis and fault diagnosis. Moreover, this integration reduces complexity by unifying information displays. It also capitalizes on the operator's existing DCS knowledge, boosting situational awareness and fostering safer, more efficient plant management.

Expert Insight: The Strategic Shift from Data Collection to Analytics

The industry's move transcends simple automation; it's a strategic reallocation of expertise. As noted by veteran reliability engineers, integrating vibration data into the DCS liberates highly skilled analysts from tedious data gathering. Their focus shifts to interpreting trends, diagnosing root causes, and optimizing machine performance. This evolution is critical for advancing from basic condition monitoring to sophisticated predictive and prescriptive maintenance models, which are central to modern digital transformation initiatives.

Solutions Scenario: Centrifugal Pump Monitoring in a Chemical Plant

A major chemical facility experienced repeated seal failures on its P-203A additive pump, causing unplanned outages every 8-10 months at a cost of approximately $85,000 per event in lost production and repair. Manual checks occurred weekly. The plant integrated Bently Nevada's 3500/42M frame (with embedded Modbus TCP) with their existing Siemens PCS 7 DCS. Continuous monitoring revealed subtle vibration increases (from 1.8 mm/s to 3.5 mm/s RMS) correlating with specific batch cycles, indicating cavitation and impending seal wear. The DCS-based alert enabled intervention during a planned batch changeover. This prevented failure, saving an estimated $340,000 over two years and extending pump mean time between repairs (MTBR) by over 300%.

The Broader Trend: OT/IT Fusion for Smarter Decisions

This integration is a key component of the larger Operational Technology (OT) and Information Technology (IT) convergence. Dedicated protection systems (OT) now feed data seamlessly into control and enterprise analytics platforms. This fusion dismantles information barriers. From an implementation standpoint, this is the foundational layer for Industrial IoT (IIoT) and machine learning applications, empowering data-driven decision-making that enhances reliability and profitability across the organization.

Implementation Roadmap: Key Steps for Successful Deployment

A successful rollout demands careful strategy. Begin with a machine criticality ranking to focus investments. Next, prioritize correct sensor selection and installation—data quality is paramount. Furthermore, collaborate early with your DCS and monitoring system vendors to test communication links and data mapping. Initiating a pilot project on one critical asset proves the concept and justifies wider expansion. This phased method controls expenditure and mitigates project risk effectively.

Conclusion: A Necessary Evolution for Modern Industry

Manual vibration collection is an obsolete tactic. Automating this function by connecting Bently Nevada's monitoring solutions to your DCS is a tactical necessity. This strategy provides superior asset reliability, minimizes unplanned downtime, and builds a robust platform for predictive care. As facilities advance their digital journeys, unifying machinery health with process control is more than an upgrade—it is a decisive step toward resilient, competitive operations.

Frequently Asked Questions (FAQ)

Q1: Can we integrate with our older DCS system?

A1: Yes, in most cases. While modern systems use OPC UA or Modbus TCP, many legacy DCS can support older protocols like Modbus RTU. A consultation with your system integrator or Bently Nevada representative can determine the optimal gateway or communication solution for your specific environment.

Q2: What's the expected return on investment (ROI) for such a project?

A2: ROI is typically rapid, often within 12-18 months. It is calculated by weighing the system cost against avoided losses from a single prevented failure. For example, preventing one $250,000 forced outage can easily justify the automation of several critical machines.

Q3: Does automated monitoring replace all need for vibration analysts?

A3> No, it redefines their role. Analysts spend less time on routes and more on deep-dive diagnostics, spectrum analysis, and advising on maintenance strategies. Their expertise becomes more strategic, focusing on preventing failures rather than just finding them.

Q4: How does this affect our functional safety and machinery protection systems?

A4> The integrated monitoring system typically complements, rather than replaces, dedicated safety systems. The Bently Nevada 3500 can provide independent, safety-certified shutdown signals via hardwired relays for critical alarms, while simultaneously sending detailed data to the DCS for operator information and trending.

Q5: What about data management and historical storage?

A5> The DCS handles short-to-medium-term historical trending. For long-term, high-resolution waveform storage and advanced analytics, data can be forwarded from the DCS or directly from the monitoring system to specialized reliability software or a data historian, creating a comprehensive asset health archive.

Check below popular items for more information in Nex-Auto Technology.