Upgrading to Allen-Bradley 1606-XLS/XLE: The Strategic Power Move for Modern Industrial Automation

With the Allen-Bradley 1606-XL series now discontinued, facility managers face a critical decision. The transition to the 1606-XLS and XLE models represents more than just a replacement—it's a strategic upgrade that delivers measurable ROI through enhanced efficiency, reliability, and space optimization in today's demanding industrial environments.

The Imperative for Power System Modernization

Maintaining discontinued equipment like the 1606-XL increases operational risk significantly. Sourcing spare parts becomes costly and time-consuming, with lead times often exceeding 12 weeks. The modern 1606-XLS and XLE series, in contrast, offers immediate availability through established distribution channels. More importantly, these newer models provide a 15-20% improvement in energy efficiency compared to legacy units, directly reducing operational costs.

Advanced Performance with Quantifiable Benefits

The engineering behind the XLS/XLE series delivers tangible advantages. The intelligent circuitry achieves up to 94% efficiency rating, reducing thermal losses by approximately 30%. This directly translates to lower cooling requirements in control panels. The built-in power reserve capability—20% continuous for XLE or 50% temporary for XLS—provides crucial headroom. For instance, during motor startup inrushes that can reach 400% of running current, this reserve prevents voltage sags that typically cause PLC resets and production interruptions.

Application Case: Automotive Manufacturing Line

A midwestern automotive plant upgraded 47 control panels from 1606-XL to 1606-XLE units across their robotic welding lines. The results were substantial: panel internal temperatures decreased by 8°C on average, extending component lifespan. More significantly, the plant eliminated 12-15 annual downtime incidents previously caused by power-related faults during simultaneous actuator operations. Their calculated ROI was achieved in just 9 months through reduced maintenance and increased production uptime.

Comprehensive Features for Global Deployments

Today's manufacturing facilities operate with globally standardized equipment. The 1606-XLS/XLE series supports this reality with universal input voltage ranges (85-264V AC for single-phase, 320-575V AC for three-phase) and comprehensive international certifications. The available redundancy modules create N+1 power configurations that have demonstrated 99.95% uptime in continuous process applications. This is particularly valuable for pharmaceutical or food processing plants where unexpected shutdowns can result in substantial product loss.

Space Optimization with Real Panel Savings

The compact design provides concrete space savings. At just 35mm width for a 240W unit, the 1606-XLE requires 40% less panel space than its predecessor. In a typical control panel with 8 power supplies, this translates to freeing approximately 280mm of horizontal space—enough to add an additional PLC or communication module without expanding the enclosure. This density advantage is becoming increasingly valuable as Industry 4.0 implementations require more devices in limited spaces.

Industry Trend Analysis: The Shift to Smarter Power Distribution

The industrial power supply market is evolving beyond basic conversion functions. Modern systems now require intelligent monitoring, predictive maintenance capabilities, and seamless integration with plant-wide energy management systems. While the 1606-XLS/XLE represents the current standard, forward-looking operations should consider how their power infrastructure will interface with emerging IoT platforms. My recommendation is to implement modular power systems today that can accommodate future smart monitoring add-ons without complete replacement.

Solution Scenario: Water Treatment Facility Upgrade

A municipal water treatment plant serving 150,000 residents replaced their aging 1606-XL power supplies with 1606-XLS units across 22 remote pumping stations. The temporary 50% power reserve proved critical during storm events when multiple pumps activated simultaneously. Previously, these surge conditions would trigger protective shutdowns. After the upgrade, the facility recorded zero power-related incidents during two major storm seasons while reducing their annual energy consumption for control systems by 18%, saving approximately $4,200 annually across all stations.

Practical Implementation Recommendations

When planning your migration, conduct a thorough audit of actual load requirements rather than relying on nameplate ratings. Many panels operate at 60-70% of theoretical maximum load. Select the appropriate model based on your peak demand patterns—continuous versus intermittent. For critical processes, always implement redundancy modules; the additional 20% investment provides 100% backup capability. Finally, document the new power architecture thoroughly, noting the enhanced capabilities for future maintenance teams.

Frequently Asked Questions (FAQ)

Q1: What is the actual cost difference between maintaining old XL units versus upgrading?

A1: While the new units have competitive purchase prices, the true savings come from reduced energy consumption (15-20% more efficient), lower cooling costs, and eliminated downtime. Most facilities achieve full ROI within 12-18 months.

Q2: How does the 50% temporary reserve work in practical terms?

A2: The 1606-XLS can deliver 150% of its rated power for up to 30 seconds. This handles motor startups, capacitor charging, or solenoid bank activation without voltage drop that could disrupt sensitive control electronics.

Q3: Can these power supplies integrate with plant energy management systems?

A3> While not native IoT devices, their efficiency and reliability data (through connected monitoring devices) can contribute to overall energy optimization strategies. Many plants use current monitors to track performance trends.

Q4: What panel space savings can I realistically expect?

A4: Depending on your configuration, space reduction ranges from 30-45%. A typical panel with six 240W units gains approximately 210mm of horizontal space—enough for additional components or better airflow.

Q5: Are there specific industries where this upgrade delivers exceptional value?

A5: Industries with high energy costs, stringent uptime requirements, or space-constrained panels see the fastest ROI. This includes automotive, food processing, pharmaceuticals, and material handling where power quality directly affects throughput.

Check below popular items for more information in Nex-Auto Technology.

| Model | Title | Link |

|---|---|---|

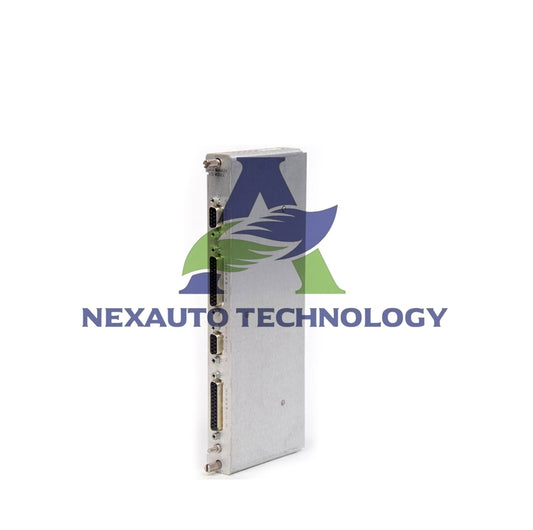

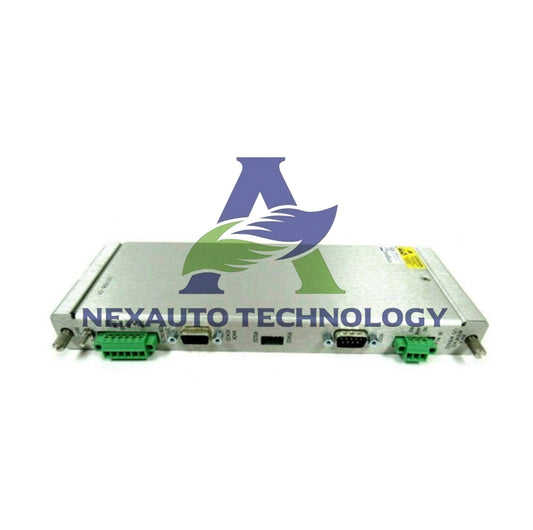

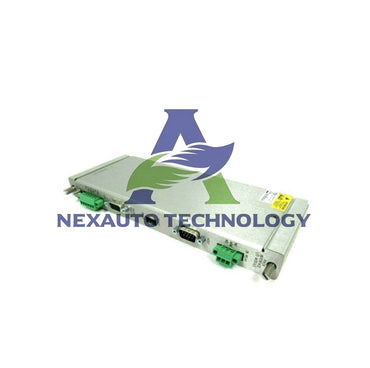

| 1606-XL120DR | Allen-Bradley Switched Mode Power Supply | Learn More |

| 1606-XLE240E | Allen-Bradley Power Supply Module | Learn More |

| 1606-XLS960E | Allen-Bradley Power Supply Module | Learn More |

| 1606-XLSDNET8 | Power Supply Module - Allen-Bradley | Learn More |

| 1606-XL180B | Allen-Bradley 180W DIN Rail Power Supply | Learn More |

| 1606-XL480E-3W | Allen-Bradley Three-Phase Power Supply | Learn More |

| 1606-XL720E-3 | 720W 3-Phase Power Supply - Allen-Bradley | Learn More |

| 1606-XLDC92D | Allen-Bradley DC/DC Converter (92W) | Learn More |