Driving Adaptive Manufacturing: The Versatile Role of 22F Series I/O Modules

Modern manufacturing demands adaptable control solutions. Consequently, robust I/O modules have become essential. Rockwell Automation's Allen-Bradley 22F Series provides a powerful interface, connecting seamlessly with PLCs and distributed control systems. This integration is vital for modern, flexible automation architectures.

Key Characteristics of 22F I/O Modules

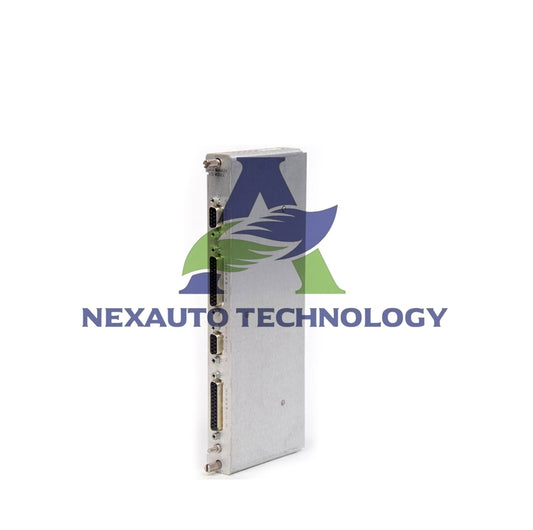

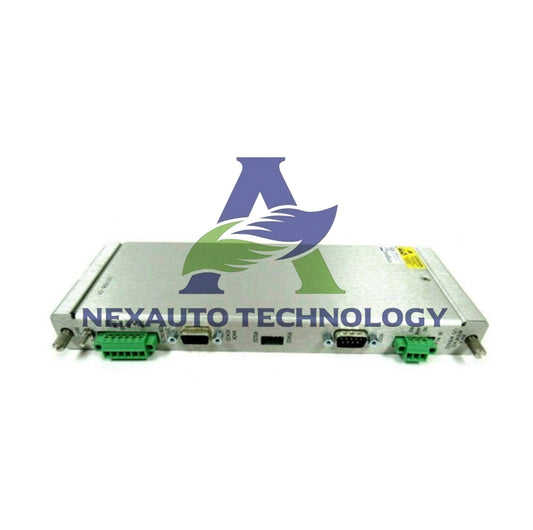

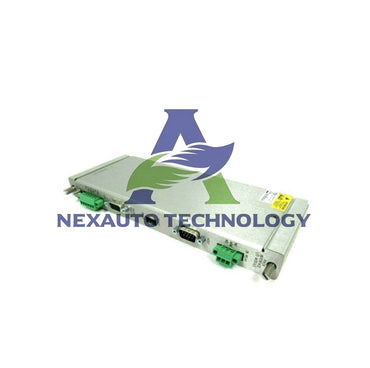

The Allen-Bradley 22F family specializes in digital input interfacing. Models such as the 22F-A011N103 offer 11-point configurations for diverse needs. Moreover, space-saving designs like the 22F-A1P6N103 suit compact control panels. Each unit reliably manages signals between field components and the central processor, ensuring data integrity.

Building Smarter Control System Networks

These modules function as crucial connection points within industrial networks. They link numerous sensors and actuators to the main controller. As a result, plants can implement more distributed and fault-tolerant designs. This approach significantly lowers wiring costs and accelerates diagnostic processes.

Real-World Application and Measurable Outcomes

An automotive production plant recently upgraded a welding line with 22F-A2P5N113 modules. The system integrated data from 180+ proximity sensors across 20 robotic cells. Therefore, diagnostic capability improved by 35%, and the average repair time decreased by 30%. In a food packaging facility, 22F-A4P2N103 modules monitored filling and capping stations. This implementation, managing 120 digital points, helped reduce product waste by 18% annually.

Industry Shift Towards Modular Design

The industrial sector increasingly favors modular and scalable components. The 22F Series meets this demand effectively. From my perspective, the range's flexibility, offering varied densities like 8-point and 17-point modules, is a major benefit. Engineers can optimize each control cabinet for cost and space. Furthermore, the rugged construction guarantees reliable operation in demanding conditions like high vibration or temperature swings.

Strategic Selection for Maximum Efficiency

Choosing the optimal I/O module requires strategic analysis. Planning must consider total I/O count, electrical specifications, and network layout. Therefore, a thorough review of current and projected device lists is crucial. A blended approach, utilizing both standard and high-density modules, often delivers the best return on investment and system performance.

Proven Solutions in Action: Case Study Highlights

Wastewater Management Facility: A plant deployed 22F-B017N103 modules to monitor pump clusters and filter banks. The system consolidated signals from over 300 field devices. Consequently, engineers achieved a 22% faster response to level alarms and cut monthly energy usage by 12% through optimized pump cycling.

Semiconductor Fabrication: A cleanroom environment used 22F-A8P0N103 modules for critical environment monitoring. The modules connected to pressure and airflow sensors. This setup provided precise data, contributing to a 40% improvement in mean time between failures (MTBF) for the environmental control system.

Expert Insights and Future Outlook

The convergence of IT and OT (Operational Technology) is reshaping I/O requirements. Future modules may embed more diagnostic intelligence. In my view, the 22F platform's design philosophy aligns with the need for future-ready, data-rich infrastructure. Investing in such versatile I/O forms a solid foundation for data-driven manufacturing and Industry 4.0 initiatives.

Frequently Asked Questions (FAQ)

Q1: How do 22F Series modules improve a control system?

A1: They provide a reliable and flexible interface for digital field devices, enabling cleaner system architecture, easier maintenance, and better data collection for diagnostics.

Q2: What is the significance of the part number suffixes?

A2: Suffixes like "N103" specify critical attributes such as input voltage range and terminal block type. Always refer to the official product catalog for exact details.

Q3: Are 22F modules suitable for machine safety systems?

A3: No. These are standard control modules. Safety-rated applications require components specifically designed and certified for functional safety, such as Allen-Bradley Guard I/O.

Q4: What factors determine the choice of module density?

A4: Consider the physical grouping of field devices and future expansion needs. Higher-density modules (e.g., 17-point) optimize panel space, while lower-density versions offer granularity for machine cells.

Q5: Is the 22F Series compatible with legacy ControlLogix or CompactLogix platforms?

A5: Compatibility is platform-specific. It is essential to verify with the latest Rockwell Automation compatibility matrix or consult a certified systems integrator before integration.

Check below popular items for more information in Nex-Auto Technology.

| Model | Title | Link |

|---|---|---|

| 22F-A011N103 | 22F-A011N103 PowerFlex 4M AC Drive Allen Bradley | Learn More |

| 22F-A011N113 | 22F-A011N113 AC Drive Allen Bradley | Learn More |

| 22F-A1P6N103 | 22F-A1P6N103 Allen Bradley PowerFlex 4M AC Drive | Learn More |

| 22F-A1P6N113 | PowerFlex 4M AC Drive Allen Bradley 22F-A1P6N113 | Learn More |

| 22F-A2P5N103 | AC Drive 22F-A2P5N103 Allen Bradley | Learn More |

| 22F-A2P5N113 | 22F-A2P5N113 Adjustable Frequency AC Drive Allen Bradley | Learn More |

| 22F-A4P2N103 | 22F-A4P2N103 Allen Bradley PowerFlex 4M AC Drive | Learn More |

| 22F-A4P2N113 | Allen Bradley PowerFlex 4M AC Drive 22F-A4P2N113 | Learn More |

| 22F-A8P0N103 | AC Drive 22F-A8P0N103 Allen Bradley PowerFlex 4M | Learn More |

| 22F-A8P0N113 | 22F-A8P0N113 Adjustable Frequency AC Drive | Learn More |

| 22F-B012N103 | AC Drive Allen Bradley 22F-B012N103 | Learn More |

| 22F-B017N103 | 22F-B017N103 Allen Bradley AC Drive | Learn More |