GE IS420UCSCS2A Controller | Mark VIeS Safety SIL 3

Bulk Orders & Fast Shipping

Instant 10% Discount On Winter Banks Credit/Debit Cards EMI and CreditCard

Fast & Reliable Worldwide Shipping – Ready to Dispatch from Stock

- Fast shipping

- Return Policy

- Lowest Price

- Help Center 24/7

-

Vendor:

General Electric

-

Type:

Controller Module

- Tags Controller module

About the Product

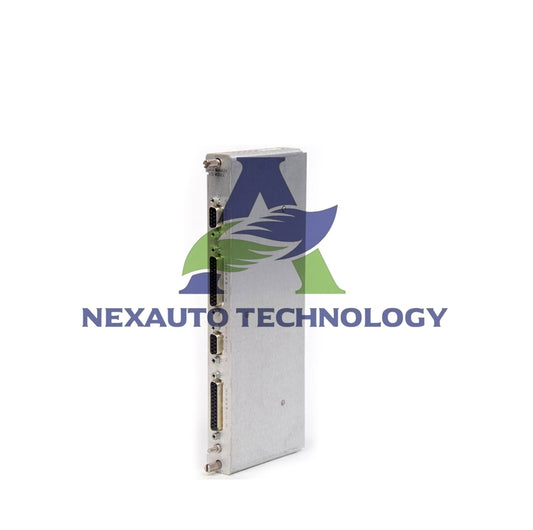

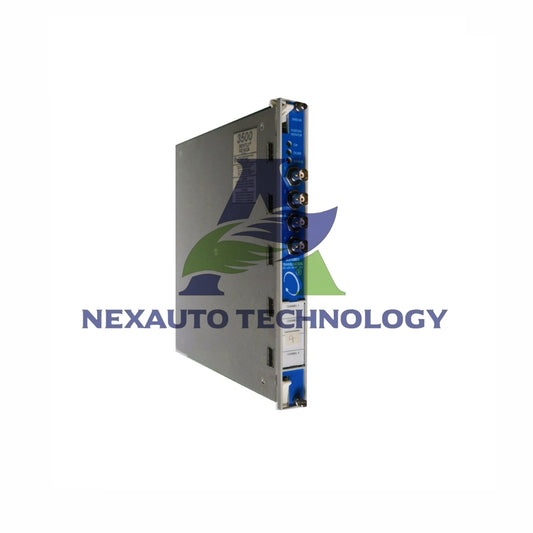

The General Electric IS420UCSCS2A is a high-performance dual-core controller module for the Mark VIeS Safety control system, engineered for critical Safety Instrumented System (SIS) applications. This compact, rugged controller delivers the processing power and reliability required to achieve SIL 2 and SIL 3 capability in functional safety loops for turbines and industrial processes.

Core Technical Specifications

- Brand & Model: General Electric IS420UCSCS2A

- Series: Speedtronic Mark VIeS Functional Safety System

- Module Type: Dual-Core Safety Controller (UCSC)

- Processor: Dual-core 1.6 GHz AMD G-Series.

- Memory: 2 GB DDR3-1066 SDRAM; 128 GB storage.

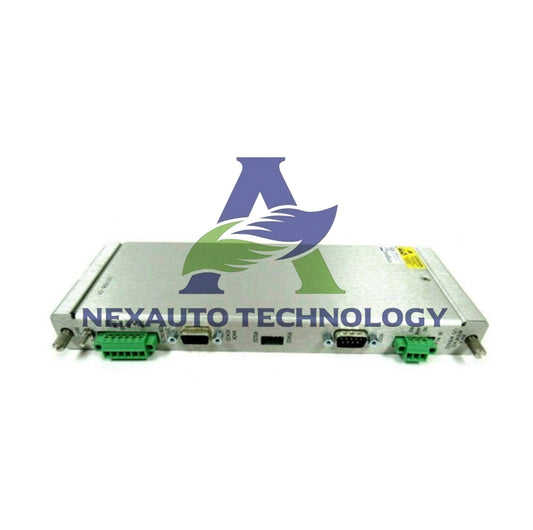

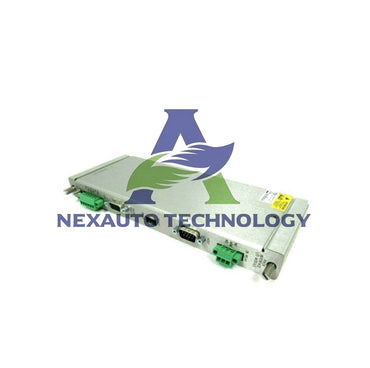

- Power Supply: 28 VDC nominal (18 - 32 VDC range).

- Mounting: DIN-rail mounting.

Performance & Safety Features

- Safety Integrity: Certified for Safety Integrity Level (SIL) 2 and SIL 3 per IEC 61508 standard.

- Redundancy Support: Configurable for Simplex, Dual, or Triple Modular Redundant (TMR) architectures.

- Operating System: Runs on QNX Neutrino real-time operating system (RTOS).

- Thermal Protection: Dual-level over-temperature protection with warnings and automatic shutdown/reboot logic.

- Software Support: Requires ControlST software version V07.02 or later.

Physical & Environmental Data

- Dimensions (HxWxD): 168 mm x 150 mm x 55 mm.

- Weight: 1,327 g.

- Operating Temperature: -40°C to +70°C.

- Robust Design: No battery, no fan, and no hardware jumpers for maximum reliability.

Connectivity & System Integration

- Communication Networks: On-board I/O network (IONet) for Mark VIe/S I/O packs, PROFINET, High-speed Serial Link (HSSL), and other interfaces.

- Expansion: Can be expanded to include up to seven additional I/O network ports.

- Gateway Function: Can interface with non-safety Mark VIe controllers (like IS420UCSCH1B) via Ethernet for data exchange (EGD protocol, OPC UA, Modbus).

Applications & System Role

- Primary Use: Executes safety-critical control logic (Safety Instrumented Functions - SIFs) in gas/steam turbines, wind turbines, combined-cycle plants, and other high-risk industrial processes.

- System Role: Serves as the central safety controller within the Mark VIeS distributed control and safety system.

- Configuration: All configuration and programming is performed via GE's ToolboxST software on a Windows PC; settings are stored in flash memory.

Frequently Asked Questions (FAQ)

What makes this a "safety" controller compared to a standard PLC?

It is specifically designed, certified (IEC 61508), and programmed for Safety Instrumented Systems (SIS). Its hardware, firmware, and development tools incorporate features like fault detection, diagnostics, and predictable response times to achieve defined Safety Integrity Levels (SIL 2/3), which are required to mitigate risk in critical safety functions.

What does the over-temperature protection do?

It has a two-tier system. The controller logic generates a warning at 85°C and safely shuts down at 95°C, rebooting automatically when cooling below 75°C. The microprocessor independently warns at 105°C and forces a shutdown at 107°C, requiring a manual power cycle to restart, protecting the hardware from damage.

Can I use standard Mark VIe I/O packs with this safety controller?

Yes, the IS420UCSCS2A communicates with both Mark VIe and Mark VIeS I/O packs via its IONet interfaces. However, for a safety loop to maintain its SIL rating, all components (sensor, logic solver, actuator) must be suitable for safety applications.

How is redundancy configured?

Redundancy (Dual or TMR) is configured within the ControlST/ToolboxST software. You define the redundancy scheme, and the system handles the synchronization and voting between multiple controller modules automatically.

What is needed to program and maintain this controller?

You need GE's ToolboxST engineering software (V07.02+) running on a Windows PC, connected to the controller's network. All configuration, logic programming, and diagnostics are performed through this software interface.

Quick Quotes & Info

- Quick Quotes: Receive pricing and availability fast from our dedicated customer service team.

- Delivery: Expedited, freight, and international shipping available worldwide.

- Warranty: NexAuto offers a 12-month warranty on all parts purchased from us, in addition to any manufacturer coverage.

- Returns: 30-day return policy for defective or mismatched parts, ensuring peace of mind.

- Payment: Flexible options including major credit cards, PayPal, and bank transfers.

- Custom Calibration: Provide your specifications, and we’ll handle the rest with precision.

Industrial Electrical Solutions

Comprehensive Automation Equipment for Every Facility

PLCs, HMIs, Servo Drives, Sensors, and Cables for reliable operations.

BENTLEY NEVADA

Condition Monitoring Solutions

Proximity probes, sensors, and monitoring systems to protect critical machinery.

ALLEN-BRADLEY

Industrial Automation Components

High-quality PLCs, HMIs, and I/O modules for reliable control systems.

HONEYWELL

Controllers, I/O & Interface Modules

New parts to support DCS platforms and PLC installations.

Blog posts

-

What Are the Key Factors in Selecting a Fieldbus for PLC and DCS Systems?

This guide provides a strategic framework for selecting the optimal fieldbus protocol in industrial automation,...

-

How Do Sensor Codes Optimize Industrial Monitoring?

This article explores how Bently Nevada's structured sensor part numbering system enhances industrial monitoring, enabling...

-

How Do Modern I/O Modules Boost Plant Efficiency?

Modern industrial automation relies on robust and intelligent I/O modules to drive efficiency. This article...