Digital or Analog Sensing: How to Select the Right Input for Your Industrial Control System?

Choosing the correct sensor signal type is a critical decision in factory automation. This selection influences cost, system design, and performance in PLC and DCS environments. This guide provides a clear comparison to inform your next project.

Understanding Fundamental Signal Differences

Digital inputs detect binary states like on or off. They are ideal for monitoring device status or event triggers. However, analog inputs capture variable data across a continuous spectrum. These sensors measure exact parameters such as fluid pressure or thermal readings.

Critical Selection Criteria for Engineers

First, determine the necessary level of measurement detail. Digital sensors work for basic state recognition. Analog devices are mandatory for precise variable tracking. Moreover, assess the operating environment and electrical noise. Leading manufacturers like Rockwell Automation and Siemens provide durable components for tough industrial conditions.

Installation and Hardware Considerations

Digital sensors generally simplify electrical connections and lower component expenses. In addition, they support quicker controller processing times. Analog sensors require specialized input cards and shielded cabling. As a result, they increase initial configuration complexity and project investment.

Real-World Application Scenarios with Data

A chemical processing facility offers a practical example. Digital sensors confirm valve positions (open or closed) for safety sequences. Meanwhile, analog sensors track reactor vessel temperature using a 4-20mA signal representing 50°C to 250°C. This dual approach ensures both safety and precise process control. In packaging, digital photo-eyes count products, while analog load cells measure material weight to within 0.5% accuracy.

Industry Trends: The Rise of Smart Sensors

The market is shifting towards intelligent devices with embedded diagnostics. IO-Link technology enables digital communication of detailed parameter data. Therefore, modern systems can blend simplicity with advanced monitoring. In my assessment, this hybrid strategy offers superior data depth while optimizing network bandwidth.

Ensuring Long-Term System Accuracy and Trust

Compliance with IEC 61131-2 guarantees electrical compatibility. For vital control loops, use high-fidelity 16-bit analog modules. Their resolution minimizes error to below 0.1%. Implement a scheduled calibration routine. This discipline maintains performance standards and builds operational confidence over years of service.

Practical Implementation Strategy

Begin by meticulously analyzing your process needs. Apply digital inputs for safety interlocks and object detection. Deploy analog inputs for all critical proportional control, like regulating flow at 100 L/min ±2%. I advocate for a scalable control platform. This flexibility allows seamless integration of both signal types as application demands evolve.

Solutions in Action: Automotive Assembly Case

An automotive plant uses digital sensors to verify robotic weld gun closure (500ms response time). Concurrently, analog torque sensors measure bolt tightening force (target: 120 Nm ±5 Nm). This combination guarantees structural integrity and traceability. The system processes over 2,000 digital and 150 analog signals per station, demonstrating robust hybrid architecture.

Expert Commentary and Future Outlook

Networked smart sensors represent the clear future. They reduce wiring by 30% and provide predictive maintenance data. My recommendation is to specify sensors with dual digital/analog capabilities for new installations. This forward-thinking approach protects your investment against upcoming technological shifts in Industry 4.0.

Frequently Asked Questions (FAQ)

Q1: Can one device provide both discrete and analog data?

A1: Yes. Modern "smart" sensors with IO-Link can transmit both a process value (analog) and a device status (discrete) over a single cable.

Q2: Which is more cost-effective for basic monitoring?

A2: Discrete inputs are typically more economical for simple state detection, due to lower sensor and module costs.

Q3: How does signal interference affect analog vs. discrete inputs?

A3: Analog signals are more susceptible to electrical noise, which can distort measurements. Discrete signals are more noise-immune for on/off states.

Q4: What is a typical analog signal range in industrial controls?

A4: The 4-20mA current loop is most common, where 4mA represents the minimum scale and 20mA the maximum.

Q5: When should I absolutely choose an analog input?

A5: Always choose analog when you need to know the exact magnitude of a variable, such as temperature, pressure, level, or flow rate for precise control.

Check below popular items for more information in Nex-Auto Technology.

| Model | Title | Link |

|---|---|---|

| EVF9330-EV | Lenze EVF9330-EV 74 HP Frequency Inverter | Learn More |

| EVF9336-EVV110 | Frequency Inverter Module Lenze EVF9336-EVV110 | Learn More |

| EVF9383-EVV030 | Lenze EVF9383-EVV030 550 HP Frequency Inverter | Learn More |

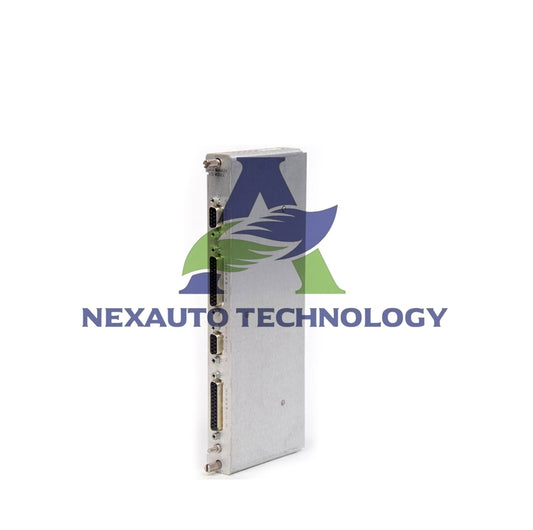

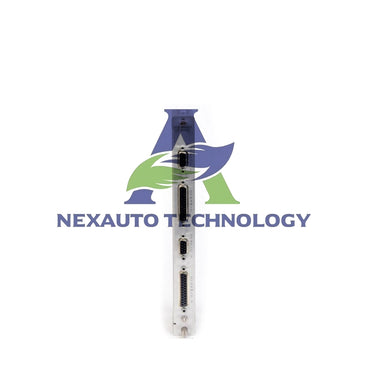

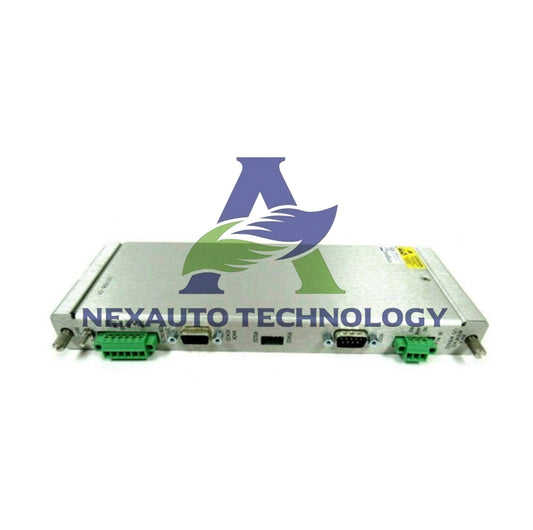

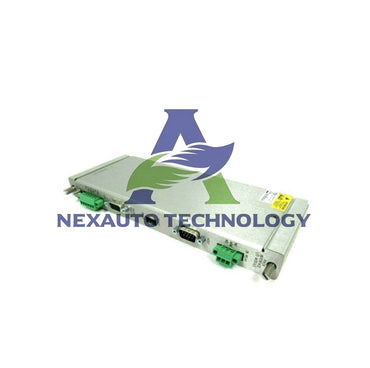

| EVS9325-CPV003 | Lenze EVS9325-CPV003 Servo Drive | Learn More |

| EVS9321-CPV003 | EVS9321-CPV003 Lenze Servo Controller | Learn More |

| EVS9326-CRV003 | Lenze EVS9326-CRV003 Servo Register Controller | Learn More |

| 330103-00-08-10-12-CN | Bently Nevada 330103-00-08-10-12-CN 8mm Proximity Probe | Learn More |

| 330103-00-11-10-12-CN | Bently Nevada 330103-00-11-10-12-CN 8mm Proximity Probe | Learn More |

| 330103-00-18-10-12-CN | Proximity Probe Bently Nevada 330103-00-18-10-12-CN | Learn More |

| 330103-00-13-10-12-CN | Bently Nevada Proximity Probes 330103-00-13-10-12-CN | Learn More |

| 330102-00-40-05-01-00 | Bently Nevada 330102-00-40-05-01-00 8mm Proximity Probe | Learn More |

| 330102-00-17-50-11-CN | Bently Nevada 330102-00-17-50-11-CN Proximity Probe with Armor | Learn More |

| 330102-02-25-20-02-00 | Bently Nevada 330102-02-25-20-02-00 Armored Proximity Probe | Learn More |

| 330191-00-08-05-05 | Proximity Probes Bently Nevada 330191-00-08-05-05 | Learn More |

| 140AVO02000C | Schneider Electric 140AVO02000C Analog Output Module | Learn More |

| 140CPS41400C | Schneider Electric 140CPS41400C Power Supply Module | Learn More |

| 140CPS42400C | 140CPS42400C 5.1V 8A Redundant Power Module Schneider | Learn More |

| 140CPU21304C | Schneider Electric 140CPU21304C CPU Module | Learn More |

| 140CPU42402C | Modicon Quantum 140CPU42402C 486 CPU Schneider | Learn More |

| 140DAI34000C | Schneider Electric 140DAI34000C 16-Channel DI Module | Learn More |

| 140DAI35300C | Schneider Electric 140DAI35300C 24VAC 32 Point DI | Learn More |

| 140DAI54300C | Schneider Electric 140DAI54300C Discrete Input Module | Learn More |

| 140MMD10200 | Schneider Electric 140MMD10200 Motion Control Module | Learn More |

| 990NAA21510 | Schneider Electric 990NAA21510 Programming Cable | Learn More |

| 330104-00-05-10-12-05 | Bently Nevada 330104-00-05-10-12-05 Proximity Probe | Learn More |

| 31000-00-00-00-031-01-02 | 31000-00-00-00-031-01-02 Bently Nevada Proximity Probe | Learn More |

| 330174-00-08-50-02-05 | Bently Nevada 330174-00-08-50-02-05 5mm Probe | Learn More |

| 330171-21-36-10-02-05 | Bently Nevada 330171-21-36-10-02-05 Probe | Learn More |

| 330905-08-13-10-12-00 | Bently Nevada 330905-08-13-10-12-00 NSV Probe | Learn More |